1. Maintain a stable temperature:

One of the primary functions of insulated bulk containers is to maintain the required temperature stability of the cargo. This is critical for many industries, especially in the food, pharmaceutical and chemical sectors. By using insulated containers, temperature fluctuations during transportation can be minimized, ensuring that goods remain stable within a specified temperature range. For example, fresh frozen food needs to be transported at extremely low temperatures, and insulated containers can prevent the goods from thawing, thus maintaining the freshness of the food.

2. Prevent temperature gradients:

There is usually no temperature gradient within an insulated container, meaning that every part of the cargo is subject to the same temperature effects. In contrast, traditional cargo transportation may result in partial damage to the cargo due to temperature differences that may exist at different locations within the container. Insulated containers help reduce this type of cargo loss by evenly distributing temperature.

3. Reduce the effects of humidity and moisture:

Some shipments are very sensitive to humidity and humidity and may be damaged in high humidity environments. Insulated containers usually have moisture-proof properties, which can effectively reduce the impact of humidity and moisture on goods. This is particularly important when transporting extremely moisture-sensitive cargo such as electronic equipment, electronic components and chemicals. By insulating containers, a dry environment can be maintained and loss and corrosion of goods can be reduced.

4. Provide physical protection:

Insulated containers are usually made of sturdy materials that offer good durability. These containers can effectively protect goods from external physical factors such as collision, crushing and shock. This helps reduce breakage and damage to goods during transportation. For example, in the transportation of liquid chemicals, the strong performance of insulated containers can protect the goods from external extrusion forces and impacts, ensuring safety and quality.

5. Reduce gas exchange:

Insulated containers are usually designed to be airtight, reducing gas exchange between the cargo and the external environment. This is very helpful in preventing goods from rotting, oxidizing or deteriorating, especially for goods that are susceptible to contamination such as food, pharmaceuticals and chemicals. By reducing gas exchange, insulated containers effectively isolate the interaction between the cargo and the outside environment.

6. Provide cargo tracking and monitoring:

Some insulated containers are equipped with monitoring systems that can track the temperature, humidity and status of the goods in real time. This enables shipping companies and logistics professionals to quickly detect issues and take action to reduce cargo losses. For example, in cold chain logistics, if the temperature inside an insulated container suddenly rises, the monitoring system will immediately issue an alarm so that necessary measures can be taken to avoid cargo loss.

7. Reduce shipping time:

The temperature control features of insulated containers help goods reach their destination faster. This reduces the time the cargo is exposed to adverse conditions in transit, thereby reducing the risk of cargo loss. For example, in cold chain logistics, quickly delivering fresh food to the market can ensure that it remains fresh and reduce food loss.

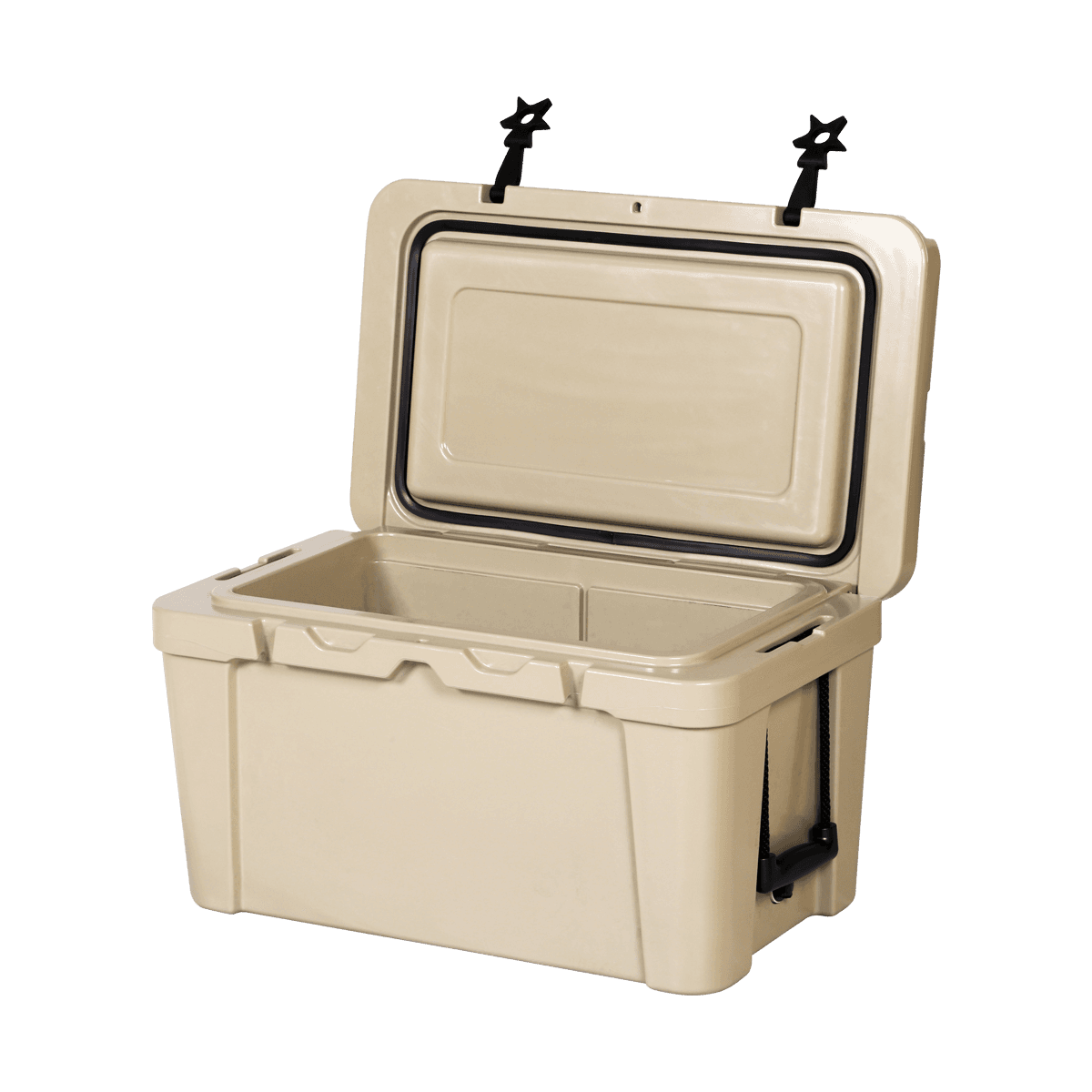

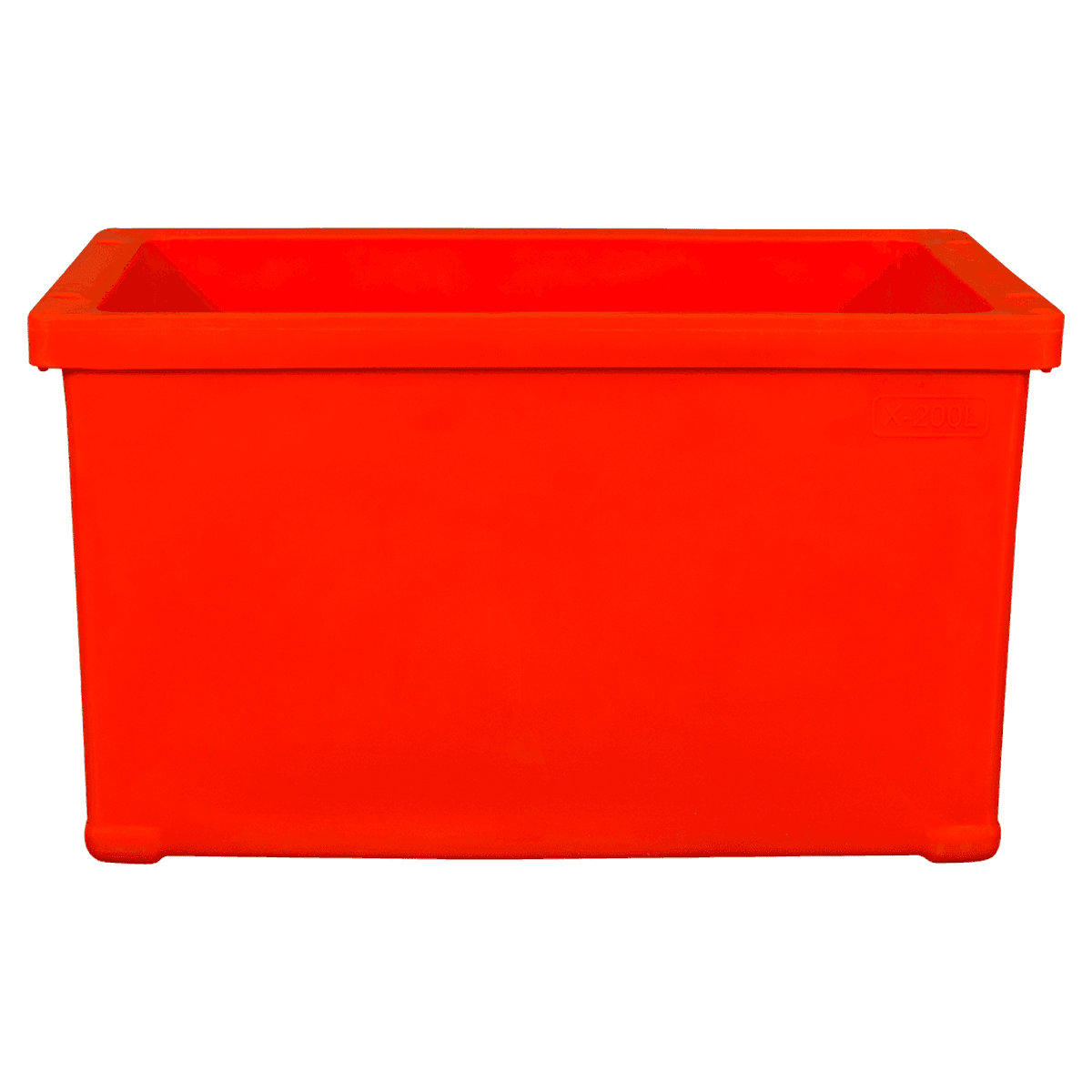

AF-660L Insulated Storage Container Meat/poultry Industrial Use Plastic Containers

AF-660L Insulated Storage Container Meat/poultry Industrial Use Plastic Containers

The PUR AF-660L insulated plastic container is one of our most popular models and a classic choice. It is particularly well suited for use within the seafood industry, both out at sea and during processing on land.AF-460L fish tub is double walled with a PUR core and a high insulation factor. It is interstackable with our AF-460L and AF-340L. It is also equipped with strong, dependable hoisting grips and has easy access on two sides for pallet jacks and all four with fork lifts.

It can be used for example as a fish tub, meat tub ,poultry container or as a food recycling container, whatever suits the customer.

English

English Español

Español عربى

عربى 中文简体

中文简体

-4.png?imageView2/2/format/jp2)

-4.png?imageView2/2/format/jp2)

-2.png?imageView2/2/format/jp2)

-2.png?imageView2/2/format/jp2)

-2.png?imageView2/2/format/jp2)