1.Thermal Insulation: Insulated pallet containers rely on advanced thermal insulation materials and construction techniques to effectively impede the transfer of heat between the container's interior and exterior environments. Expanded polystyrene (EPS), polyurethane foam, and vacuum-insulated panels (VIPs) are commonly used due to their excellent insulating properties. These materials create a thermal barrier that significantly slows down the movement of heat, thereby maintaining a stable internal temperature regardless of external conditions. EPS, for instance, is lightweight yet boasts remarkable insulation capabilities, making it a popular choice for insulating pallet containers. Similarly, polyurethane foam provides exceptional thermal resistance while offering durability and versatility in container design. Vacuum-insulated panels consist of a core material enclosed within a vacuum-sealed panel, offering superior insulation in a slim profile. By incorporating these insulation materials into the construction of insulated pallet containers, manufacturers ensure that temperature fluctuations are minimized, thereby preserving the quality and integrity of temperature-sensitive products during transportation and storage.

2.Double-Wall Construction: Insulated pallet containers often feature a double-wall construction design, which enhances their thermal insulation properties and reinforces structural integrity. This construction typically consists of an inner and outer layer, with the insulating material sandwiched between them. The outer layer is typically made from durable materials such as high-density polyethylene (HDPE), fiberglass, or metal, providing protection against external elements and mechanical stresses. The inner layer serves as a barrier between the cargo and the insulating material, ensuring that the insulation remains intact and effective. Between these layers, the insulation material, whether it be EPS, polyurethane foam, or VIPs, acts as a buffer against temperature fluctuations, maintaining a consistent internal temperature. The double-wall construction not only enhances thermal resistance but also adds strength and durability to the container, making it suitable for various transportation and storage applications. This robust construction ensures that the container can withstand the rigors of handling, stacking, and transportation while reliably preserving the temperature-sensitive cargo within.

3.Tight Seals and Closure Systems: To prevent temperature fluctuations, insulated pallet containers are equipped with tight seals and closure systems that create an airtight enclosure. These seals, typically made from rubber or silicone gaskets, form a secure barrier that prevents the ingress or egress of air. Additionally, closure systems such as latches or locking mechanisms ensure that the container remains tightly sealed during transit and storage. By maintaining an airtight seal, these containers prevent warm air from infiltrating the interior and cold air from escaping, or vice versa, thereby preserving the desired temperature inside the container. This is particularly critical for temperature-sensitive products such as pharmaceuticals, food, and chemicals, where even minor temperature deviations can compromise product quality and efficacy. The tight seals and closure systems employed in insulated pallet containers provide an effective defense against temperature fluctuations, ensuring that the cargo remains protected and stable throughout its journey in the supply chain.

4.Temperature Monitoring and Control: Many insulated pallet containers are equipped with advanced temperature monitoring and control systems that enable users to actively regulate and maintain the internal temperature. These systems typically include temperature sensors, thermostats, and heating or cooling elements integrated into the container design. Temperature sensors continuously monitor the internal temperature, providing real-time data to the control system. Based on this data, the control system activates heating or cooling elements as needed to adjust the temperature and counteract external temperature fluctuations. For example, if the ambient temperature rises above the desired range, the cooling system may be activated to lower the internal temperature accordingly. Conversely, if the ambient temperature drops too low, the heating system may be engaged to prevent the cargo from freezing. This dynamic temperature control ensures that the cargo remains within the specified temperature range, minimizing the risk of spoilage, degradation, or damage due to temperature fluctuations. Additionally, temperature monitoring systems allow users to track temperature conditions throughout the transportation and storage process, providing valuable data for quality assurance and regulatory compliance.

5.Optimized Design for Air Circulation: Proper air circulation is essential for maintaining uniform temperatures within insulated pallet containers. These containers are designed with ventilation systems that facilitate the circulation of air while minimizing heat transfer. Ventilation openings strategically positioned throughout the container allow for the exchange of air without compromising insulation integrity. Airflow patterns within the container are carefully engineered to ensure that cold air is distributed evenly, preventing localized temperature variations. Additionally, baffles or air ducts may be incorporated into the container design to control airflow and optimize temperature distribution. By promoting effective air circulation, these ventilation systems help to maintain consistent temperatures throughout the container, ensuring that temperature-sensitive products are uniformly cooled or heated during transportation and storage. This uniformity minimizes the risk of temperature gradients that could lead to product spoilage or damage, thereby enhancing product quality and shelf life.

6.Reflective Surfaces: Insulated pallet containers may feature reflective surfaces or coatings that help to reduce heat absorption from external sources such as solar radiation. These reflective materials, typically aluminum foil or metallized films, are applied to the exterior surfaces of the container to deflect incoming heat rays. By reflecting radiant heat away from the container, these surfaces help to maintain cooler internal temperatures, particularly in outdoor or sunny environments. Additionally, reflective surfaces can help to mitigate temperature fluctuations caused by external heat sources, providing an additional layer of protection for temperature-sensitive cargo. The reflective properties of these surfaces make them particularly effective in warm climates or during outdoor storage, where solar heat gain can significantly impact the internal temperature of the container. By incorporating reflective surfaces into the design, insulated pallet containers enhance their overall thermal performance and contribute to the preservation of product quality during transportation and storage.

7.Compatibility with Cold Chain Logistics: Insulated pallet containers play a crucial role in cold chain logistics, which involves the transportation and storage of temperature-sensitive products under controlled conditions. These containers are designed to integrate seamlessly into cold chain operations, providing reliable temperature control and protection for perishable goods. By maintaining consistent temperatures throughout the supply chain, insulated pallet containers help to preserve the quality, safety, and efficacy of temperature-sensitive products from production to consumption. Whether transporting pharmaceuticals, fresh produce, or frozen foods, insulated pallet containers ensure that the cargo remains within the specified temperature range, thereby minimizing the risk of spoilage, contamination, or degradation. This compatibility with cold chain logistics makes insulated pallet containers indispensable for industries such as pharmaceuticals, food and beverage, biotechnology, and healthcare, where maintaining product integrity is paramount. By safeguarding the cold chain, these containers help to ensure product quality and safety while reducing waste and mitigating financial losses associated with temperature excursions.

F-660L Insulated Fish Containers Seafood Industrial Use Plastic Containers

Imported food grade LLDPE +PU as raw material offers excellent hygiene and outstanding product protection

One-piece rotomold, more solid and durable with good sealing and strong insulation performance

With removable lid, convenient for loading and unloading of goods

Accessible by a hand pallet jack from two sides and by a forklift truck from all four sides

With stackable design, can be stacked up Four to Six boxes, increase the capacity of storage and save space

Drainage plugs easy and quick to drain water

+86-574-88768635

News

Related Products

-

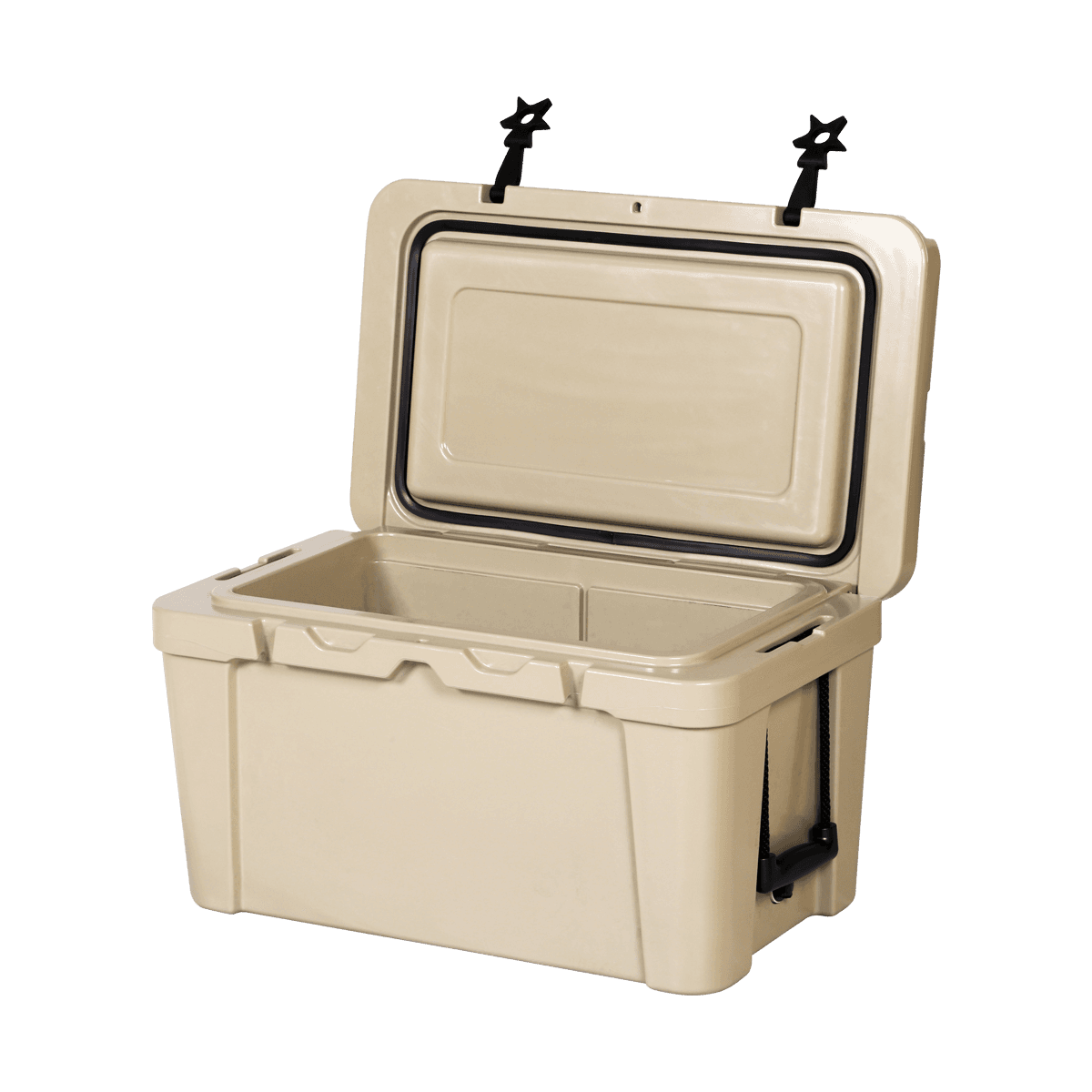

X-200L Ice Cooler Box For Seafood Storage And Transportation

-

-4.png?imageView2/2/format/jp2)

X-120L Insulated Fish Bin Ice Cooler Box

-

-4.png?imageView2/2/format/jp2)

X-70L Insulated Fishing Ice Cooler Box

-

-2.png?imageView2/2/format/jp2)

X-68L Ice Cooler Box To Keep Food Cold And Fresh

-

X-200L Short-distance Live Seafood Transportation Tanks

-

-2.png?imageView2/2/format/jp2)

X-120L Live Seafood Transportation Tanks

-

-2.png?imageView2/2/format/jp2)

X-70L Live Seafood Transportation Tanks

-

K-65L Outdoor Leisure Use Insulated Cooler Ice Box

-

K-45L Rotomolded Insulation Ice Cooler for Outdoor Camping Fishing Hunting BBQs

-

K-25L Portable Cooler Outdoor Leisure Use Cooler Box

CONTACT US

-

ADDRESS:

No. 68 Fanggang Road, Fenghua fangqiao Town, Ningbo, Zhejiang, China

-

Tel:

+86-574-88768635 / +86-13306535333 (Mr Joe)

-

E-mail:

quick link

product

LATEST news

mobile site

Copyright © 2022, Ningbo Wanma Plastics Co., Ltd. All Rights Reserved.

English

English Español

Español عربى

عربى 中文简体

中文简体