1. Material selection

The material of the insulating pallet container is the primary factor that determines its thermal insulation performance. Common insulating materials include polystyrene foam (EPS), polyurethane foam (PUR) and polypropylene (PP), which have excellent low thermal conductivity and can effectively prevent the conduction of heat. For example, the thermal conductivity of polystyrene foam is usually around 0.03 W/m·K, which is much lower than that of metal materials, making it excellent in maintaining internal temperature. The thickness of the material directly affects the thermal insulation performance. A thicker insulation layer can improve the thermal insulation effect to a certain extent, but the balance between weight and cost should also be considered. Therefore, when selecting materials, designers need to comprehensively consider thermal insulation performance, cost and weight to meet the needs of goods with different transportation requirements.

2. Container structure

The structural design of the container has an important impact on the thermal insulation performance. Pallet containers with double or multi-layer designs can form an air layer between the inner and outer layers. This air layer plays a good insulating role and can reduce heat loss. Air, as a good insulator, performs well in thermal insulation. When designing, attention should be paid to sealing. A good seal can effectively prevent external air from entering the container and reduce heat exchange. The shape of the container is also crucial. A more streamlined design can reduce wind resistance and reduce the impact of external cold air, thereby maintaining a stable internal temperature during transportation.

3. Shape and size

The shape and size of the container will affect air flow and heat distribution. A properly designed container shape can minimize heat loss. For example, smaller containers can maintain temperature faster because they have less internal space and heat is more easily locked in. However, the choice of container size also needs to take into account the volume of cargo to be transported. Oversized containers may lead to uneven internal temperature distribution, so designers need to ensure that the container size matches the cargo volume to achieve the best insulation effect. The ratio of the height of the container to the bottom area should also be reasonable to avoid tipping or instability due to a high center of gravity.

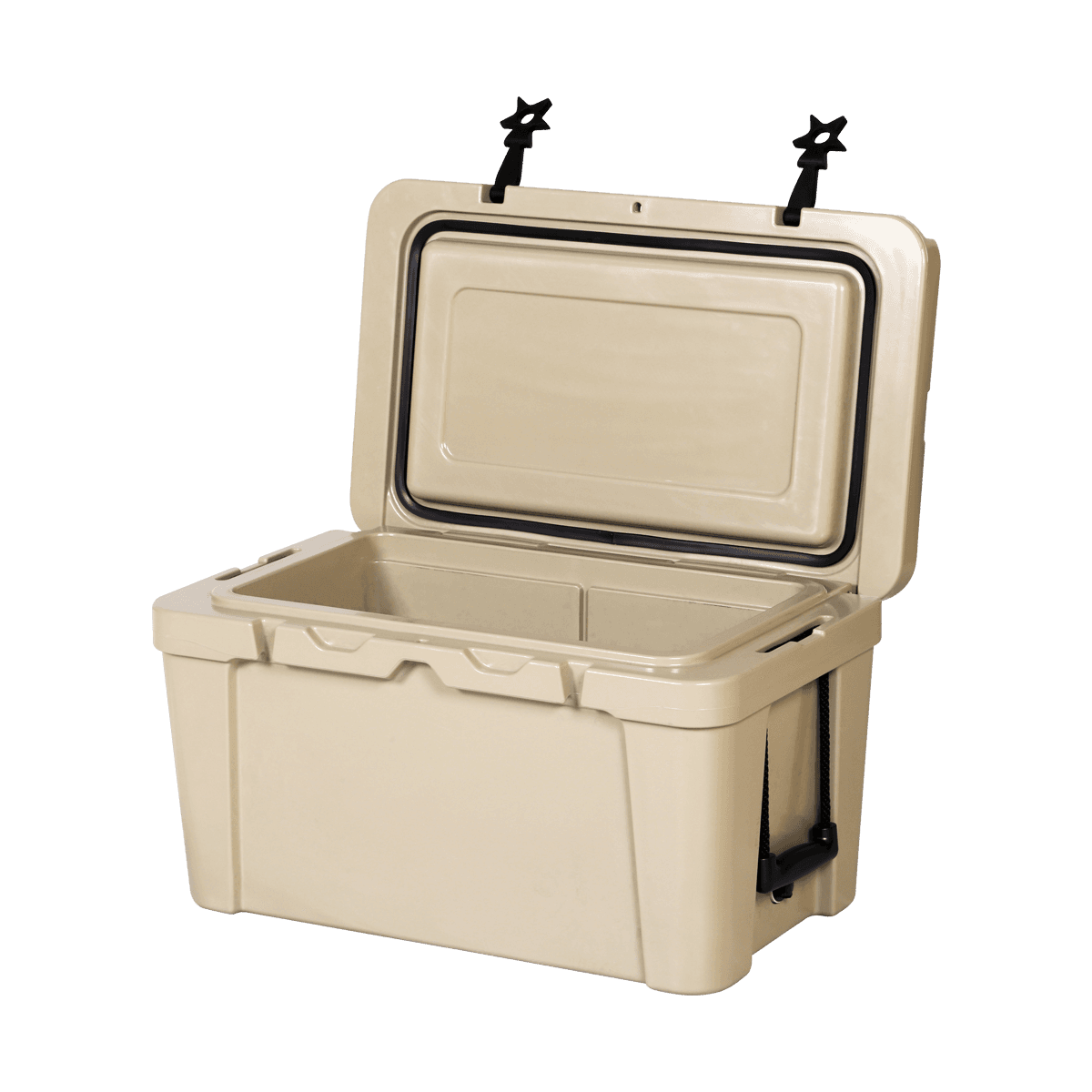

4. Insulated lid and closure system

In the design of insulated pallet containers, the use of an insulated lid can further enhance the insulation effect. High-quality insulated lids are usually made of the same or higher grade insulation material as the container, which can effectively prevent the loss of heat from the top. To enhance the seal, some container designs will also add rubber sealing strips to ensure a tight fit between the lid and the container to prevent the entry of cold air. Some high-end pallet containers are also equipped with intelligent temperature control systems that can monitor the internal temperature in real time and automatically adjust when necessary. This intelligent design not only improves thermal insulation performance, but also provides additional protection for goods, especially in extreme weather conditions.

5. Testing and standards

In the design process of insulated pallet containers, thermal performance testing is an important step to ensure its effective insulation. By simulating transportation scenarios under different environmental conditions and testing the temperature changes and heat loss of the container, designers can help optimize the container design. Complying with industry standards and regulations is also an important way to improve product competitiveness. By adopting international standards such as ASTM, ISO, etc., designers can ensure the recognition and reliability of the container in the market. The test results can not only provide a basis for subsequent improvements, but also provide customers with quality assurance, making them more trustworthy when choosing.

English

English Español

Español عربى

عربى 中文简体

中文简体

-4.png?imageView2/2/format/jp2)

-4.png?imageView2/2/format/jp2)

-2.png?imageView2/2/format/jp2)

-2.png?imageView2/2/format/jp2)

-2.png?imageView2/2/format/jp2)