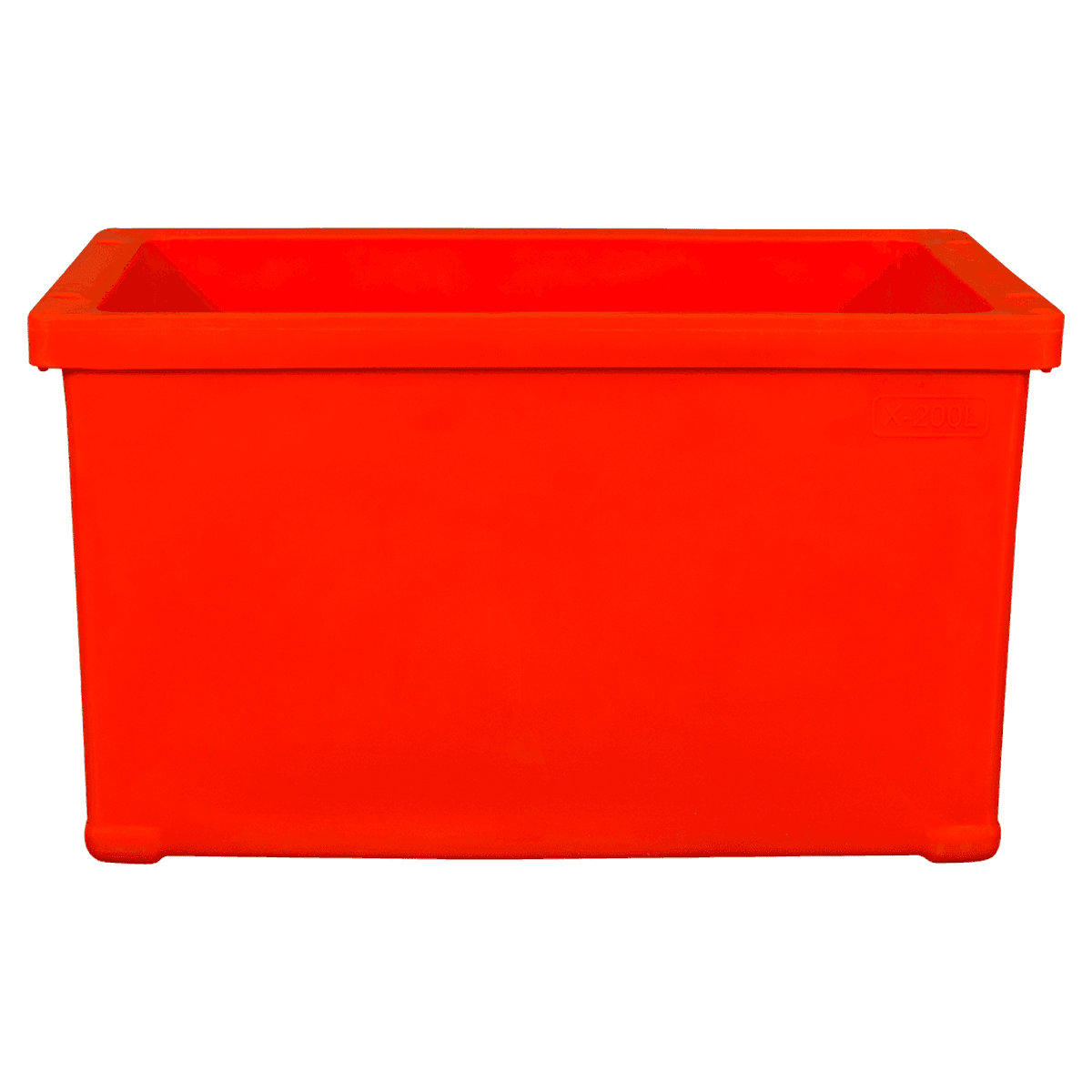

1. Enhanced insulation and temperature control

The double-layer structure of the AF-380L live seafood transport box forms an effective insulation barrier through two layers of plastic inside and outside and a solid PUR (polyurethane) core. This design ensures that the temperature inside the box can remain stable for a long time, reducing the impact of external temperature fluctuations. Temperature control is crucial for seafood, especially live fish. Fresh fish are prone to physiological changes at high temperatures, which can lead to quality degradation or death. Through the insulation layer, the AF-380L can effectively maintain a refrigerated environment, which not only slows down the temperature rise, but also prevents the temperature from dropping sharply during transportation, thereby ensuring that the fish is always in a suitable environment. For seafood that needs to be transported for a long time, such as salmon and cod, excessive temperature fluctuations will cause them to not adapt to the environment, and even affect their taste and quality. Through this double-layer insulation design, the AF-380L box can effectively extend the transportable time of fish and ensure that the fish remains fresh at the end of transportation.

2. Protection from the influence of the external environment

The double-layer structure not only provides thermal insulation protection, but also effectively protects the box from interference from the external environment. Whether it is fishing boats under the sun or rapidly changing climate conditions, the double-layer design of the AF-380L can reduce the impact of these environmental factors on the quality of seafood during transportation. During sea transportation, factors such as temperature, humidity, and wind speed will fluctuate dramatically with weather changes, especially in warm environments, where external heat is easily transferred to the inside of the box. The double-layer structure of the AF-380L effectively isolates these external changes, limiting the temperature changes in the outside world to a minimum range, ensuring that the temperature inside the box can always remain within the ideal range. The outer layer of the box can resist the erosion of natural elements such as rain and salt spray, reducing the risk of damage to seafood during transportation. Therefore, no matter what weather conditions are encountered during transportation, the AF-380L can provide a relatively stable and safe storage environment for seafood.

3. Improved durability and structural integrity

Another significant advantage of the double-layer design is the enhanced durability and impact resistance of the AF-380L container. When transporting seafood, especially when using forklifts or pallet trucks, the container often needs to withstand certain impacts and squeezes. Traditional single-layer containers are prone to cracking or deformation during such high-intensity use, which may cause leakage or damage to seafood. The AF-380L effectively improves the strength of the container through a double-layer structure, enabling it to withstand greater impact and external pressure, thereby maintaining structural integrity. Whether it is being carried on a fishing boat or distributed and delivered on land, the AF-380L can maintain its stable shape and reduce damage caused by external forces. This high-strength design can also effectively prevent the box from cracking due to accidental impact, thereby avoiding the risk of liquid leakage and cross-contamination, and further ensuring the safety and quality of seafood.

4. Reduce condensation and moisture loss

During the transportation of seafood, moisture and condensation are an issue that requires special attention. Excessive moisture can lead to a decline in the quality of fish, such as corruption, taste changes, or appearance damage. The double-layer design of the AF-380L effectively reduces the formation of condensation, thereby reducing the negative impact of moisture on seafood. The double-layer structure provides better air isolation, which reduces the temperature difference between the inside and outside of the box, thereby reducing the condensation of water vapor caused by temperature differences. This not only helps maintain the dry appearance of the fish, but also ensures that the seafood will not be damaged by excessive moisture during transportation. At the same time, the reduction in moisture can also prevent the surface of the fish from becoming soft, dehydrated or forming ice crystals, which may affect the taste and appearance of seafood. The double-layer design of the AF-380L provides a drier and more stable environment for seafood transportation, further ensuring the quality and freshness of seafood.

5. Improve transportation efficiency

Finally, the double-layer structure of the AF-380L not only improves the preservation of seafood, but also improves overall transportation efficiency. By reducing temperature fluctuations and moisture loss, the AF-380L can more effectively maintain the quality of seafood, thereby reducing losses during transportation. This means that more fresh seafood can arrive at the destination smoothly, thereby improving the efficiency of the supply chain. The high-strength design of the box also reduces the potential losses caused by damage to the box during transportation, avoiding financial losses caused by rupture or leakage. During long-term transportation, maintaining the freshness of seafood and reducing losses can not only improve economic benefits, but also enhance customer satisfaction. The AF-380L container plays a vital role in reducing losses, improving transportation efficiency and ensuring product quality through its superior structural design.

English

English Español

Español عربى

عربى 中文简体

中文简体

-4.png?imageView2/2/format/jp2)

-4.png?imageView2/2/format/jp2)

-2.png?imageView2/2/format/jp2)

-2.png?imageView2/2/format/jp2)

-2.png?imageView2/2/format/jp2)