1. Suitable insulation material selection:

The thermal stability of insulating plastic containers depends primarily on the insulating properties of the chosen material. Common insulating materials include polyurethane foam, polystyrene foam (EPS), polyethylene foam (PE), and polypropylene foam (PP). These materials are excellent at keeping outside temperatures from affecting what's inside. For example, polyurethane foam is often used in high-performance insulating containers because of its good insulating properties and superior thermal stability.

In addition, some insulated containers have internal coatings with reflective properties to reduce the effect of thermal radiation on temperature stability.

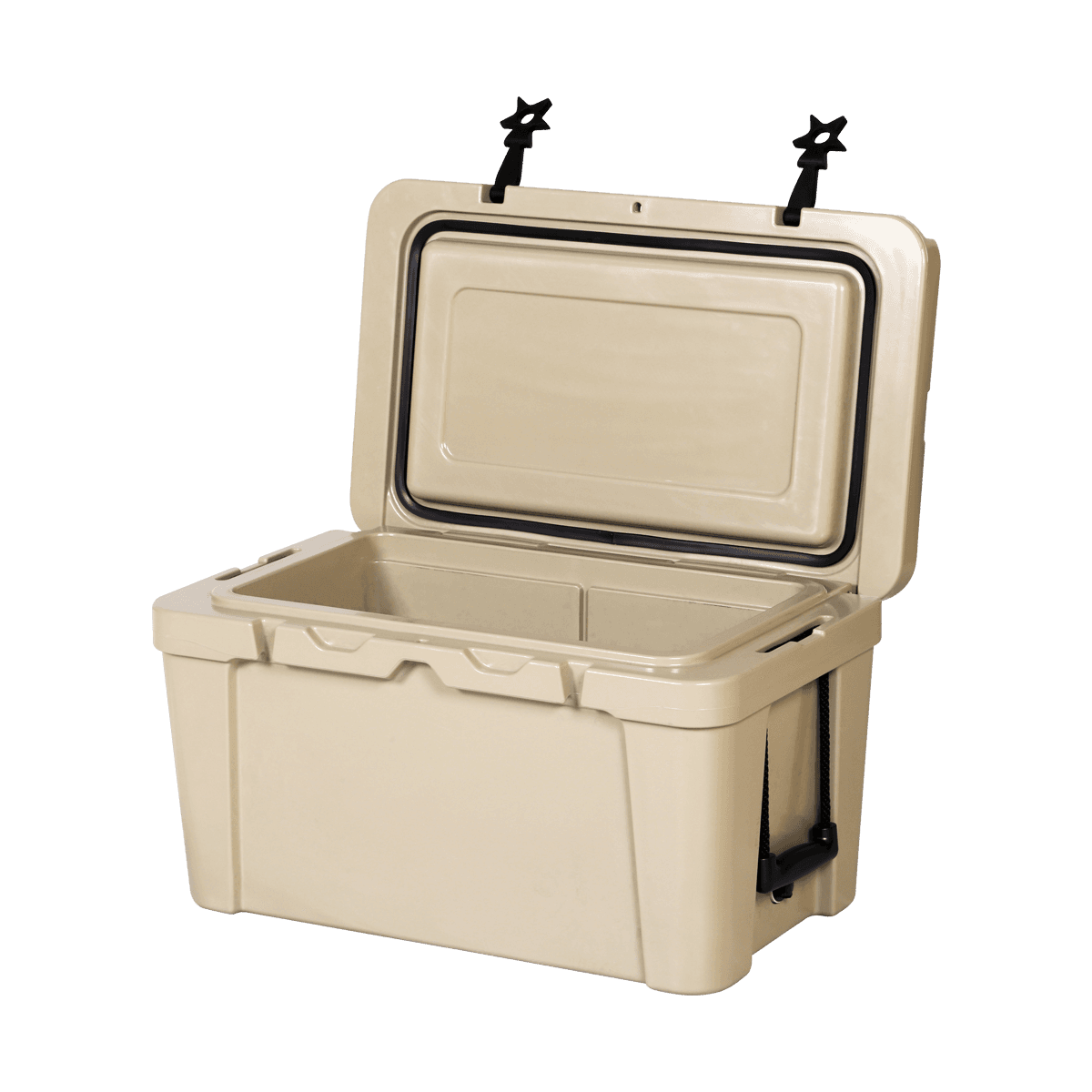

2. Sealing performance:

Insulated containers must have excellent sealing properties to ensure that the internal environment is not affected by external temperature and humidity. Sealing performance can be achieved by using high quality sealing materials and precise design process. For example, a double seal or airtight test can be used to ensure the airtight performance of the container.

3. Multi-layer insulation structure:

The performance of the insulating container can be significantly improved by adopting a multi-layer insulation structure. These multilayer structures may include different kinds of insulating materials, air interlayers or metal reflective layers. The multi-layer insulation structure helps to reduce heat conduction and convection, improving the insulation performance of the container.

4. The outer packaging of the insulating container:

Taking into account external environmental factors such as direct sunlight, humidity, and wind, choosing the right outer packaging is important to maintain temperature stability. The outer packaging should be waterproof to prevent moisture from penetrating into the container. In addition, the UV-resistant coating reduces the effect of sunlight on the temperature of the container.

5. Temperature monitoring and recording equipment:

Install temperature monitoring and recording equipment inside the insulated container to monitor and record the internal temperature in real time. These devices can provide data to help detect temperature anomalies in time and take necessary corrective actions to maintain temperature stability.

6. Proper packing method:

In insulated containers, appropriate packaging methods should be used to ensure that temperature-sensitive products are in close contact with insulating materials to reduce air movement and thereby reduce the risk of temperature changes. The packaging method should be selected according to the nature and shape of the product.

7. Pre-cooling or pre-heating treatment:

Proper pre-cooling or pre-heating before loading temperature-sensitive products ensures that the products reach the required temperature more quickly after loading. This reduces fluctuations in the temperature inside the container.

8. Training and operating procedures:

Logistics workers need training to ensure they understand the use and handling of insulated containers. Proper handling and maintenance will ensure temperature stability.

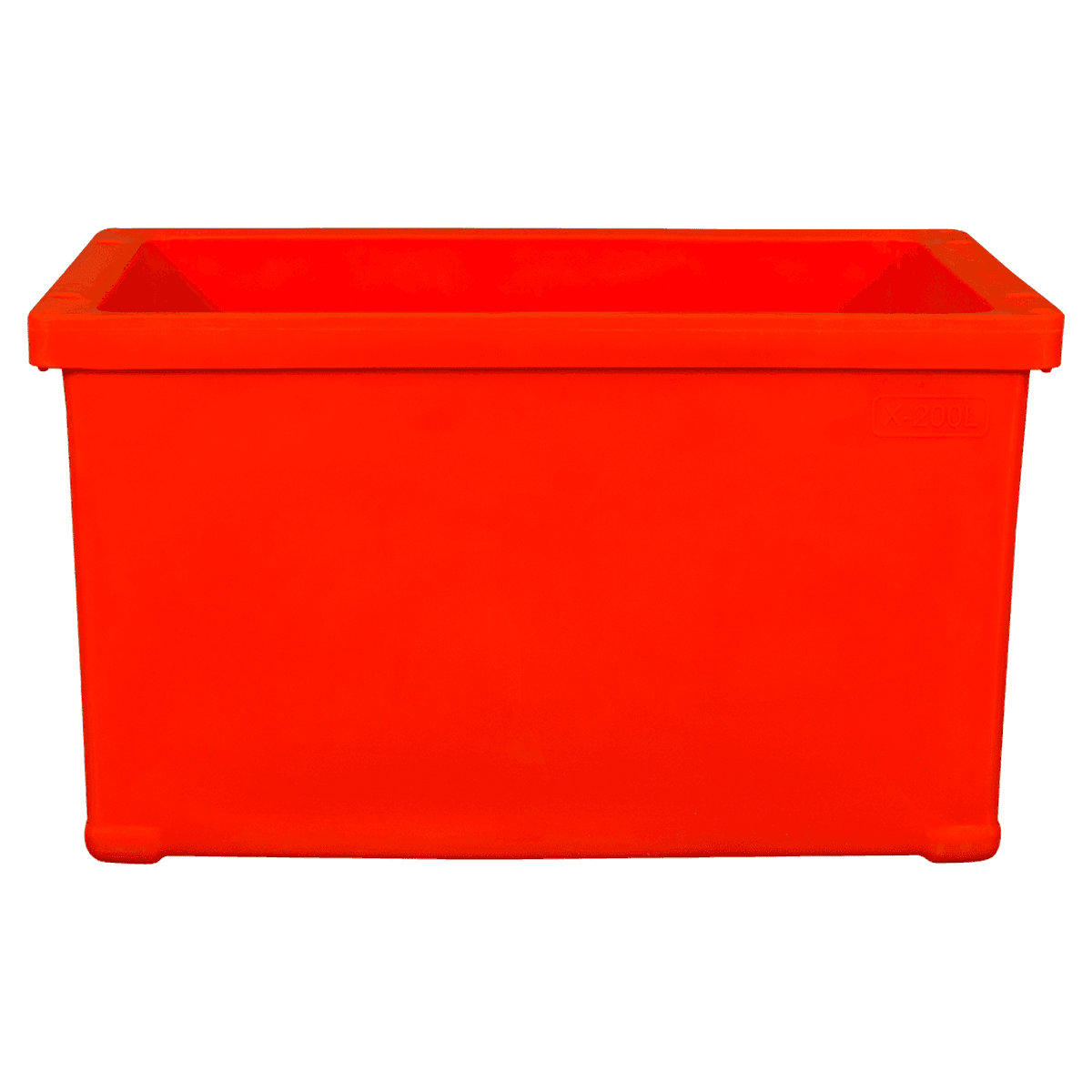

AF-1700L Extra Large Lobster Containers Seafood Industrial Use Plastic Containers

The Wanma AF-1700L PUR insulated on board handling plastic container offers a unique solution for the storage of live lobster and Tuna, handling and transportation of live lobster when use in conjunction with the 140L crates – Wanma AF-1700L insulated lobster container holds 8*140L crates for lobster. This provides an innovative solution that minimizes handing and promotes higher value ,customer satisfaction and better matketability for your lobster.

AF-1700L Extra Large Lobster Containers Seafood Industrial Use Plastic Containers

The Wanma AF-1700L PUR insulated on board handling plastic container offers a unique solution for the storage of live lobster and Tuna, handling and transportation of live lobster when use in conjunction with the 140L crates – Wanma AF-1700L insulated lobster container holds 8*140L crates for lobster. This provides an innovative solution that minimizes handing and promotes higher value ,customer satisfaction and better matketability for your lobster.

-4.png?imageView2/2/format/jp2)

-4.png?imageView2/2/format/jp2)

-2.png?imageView2/2/format/jp2)

-2.png?imageView2/2/format/jp2)

-2.png?imageView2/2/format/jp2)