1. Choose efficient oxygen supply equipment:

In order to ensure that the seafood in Live Seafood Transportation Tanks receives sufficient oxygen supply, efficient oxygen supply equipment needs to be selected. These equipment should be able to continuously and stably generate and deliver oxygen to meet the needs of seafood at different stages of transportation. Choosing high-quality, high-reliability equipment is key. They can maintain stable performance during long-term operation, reduce failure rates, and ensure the survival rate of seafood.

2. Properly design the oxygen distribution system:

When optimizing an oxygen supply system, proper design of the oxygen distribution system is crucial. By designing multiple oxygen supply points, you can ensure that oxygen can be evenly distributed to every corner of the transport tank. This prevents the oxygen concentration from being too high or too low in certain areas, thereby improving the survival rate of seafood throughout the tank. In addition, increasing the contact area between oxygen and water will also help improve the oxygen dissolution efficiency, making it easier for seafood to obtain the required oxygen.

3. Monitor and adjust oxygen concentration:

In Live Seafood Transportation Tanks, real-time monitoring and adjustment of oxygen concentration is the key to ensuring the survival rate of seafood. By installing oxygen concentration monitoring equipment, the oxygen concentration in the water tank can be understood in real time. Once it is found that the oxygen concentration is lower or higher than the appropriate range required for seafood, the operating parameters of the oxygen supply equipment need to be adjusted in time. This ensures that the oxygen concentration in the tank is always maintained at an optimal level, providing the best living environment for seafood.

4. Regular cleaning and maintenance:

To ensure the efficient operation of your oxygen supply system, regular cleaning and maintenance are essential. By regularly cleaning and inspecting equipment, problems can be discovered and solved in time to prevent equipment failure and oxygen leakage. In addition, regular replacement of filters and cleaning of water tanks can also reduce the impact of impurities and dirt on the oxygen supply system and improve the operating efficiency and stability of the system.

5. Energy saving and emission reduction:

In the process of optimizing the oxygen supply system, energy conservation and emission reduction are also important factors to consider. Choosing energy-efficient oxygen supply equipment can reduce energy consumption and transportation costs. In addition, you can also consider using renewable energy or energy-saving technologies to drive the oxygen supply system, such as solar energy, wind energy, etc. This not only reduces operating costs but also helps protect the environment.

6. Backup system:

To ensure rapid switching to backup equipment in the event of a primary oxygen supply failure, it is critical to design a backup system. A backup system can ensure that seafood can still receive adequate oxygen supply in an emergency, thus improving the survival rate of seafood. When choosing a backup system, factors such as its reliability, stability, and ease of use need to be considered.

7.Train operators:

To ensure the proper operation and maintenance of the oxygen supply system, training of operating personnel is essential. Through training, operators can become familiar with the operation and maintenance methods of the oxygen supply system, and improve their safety awareness and emergency response capabilities. In addition, operators can regularly organize skills competitions and exchange activities to promote their skill improvement and experience sharing.

8. Optimize transportation conditions:

In addition to optimizing the oxygen supply system, optimizing transportation conditions is also the key to improving the survival rate of seafood. Minimizing transportation time and distance can reduce the oxygen consumption of seafood during transportation. In addition, it is also very important to control the temperature and humidity during transportation. By maintaining appropriate temperature and humidity conditions, seafood can be kept in optimal condition during transportation and the survival rate can be increased.

9. Use oxygenating agent:

In certain circumstances, you may consider adding an appropriate amount of oxygenator to the transport tank to increase the dissolved oxygen content in the water. Oxygenating agents such as hydrogen peroxide and calcium peroxide can quickly increase the oxygen concentration in water in a short period of time. However, it should be noted that when using oxygenators, the dosage and type should be determined based on factors such as the type of seafood and transportation time to avoid adverse effects on seafood.

10. Regularly check and update:

In order to ensure the long-term stable operation of the oxygen supply system, it needs to be inspected and updated regularly. By regularly checking the performance and efficiency of equipment, problems can be discovered and solved in time, preventing equipment failures and oxygen leaks. In addition, it is also very important to pay attention to the development of new technologies and new equipment. When new technology or equipment emerges, you can consider applying it to your own oxygen supply system to improve the performance and efficiency of the system.

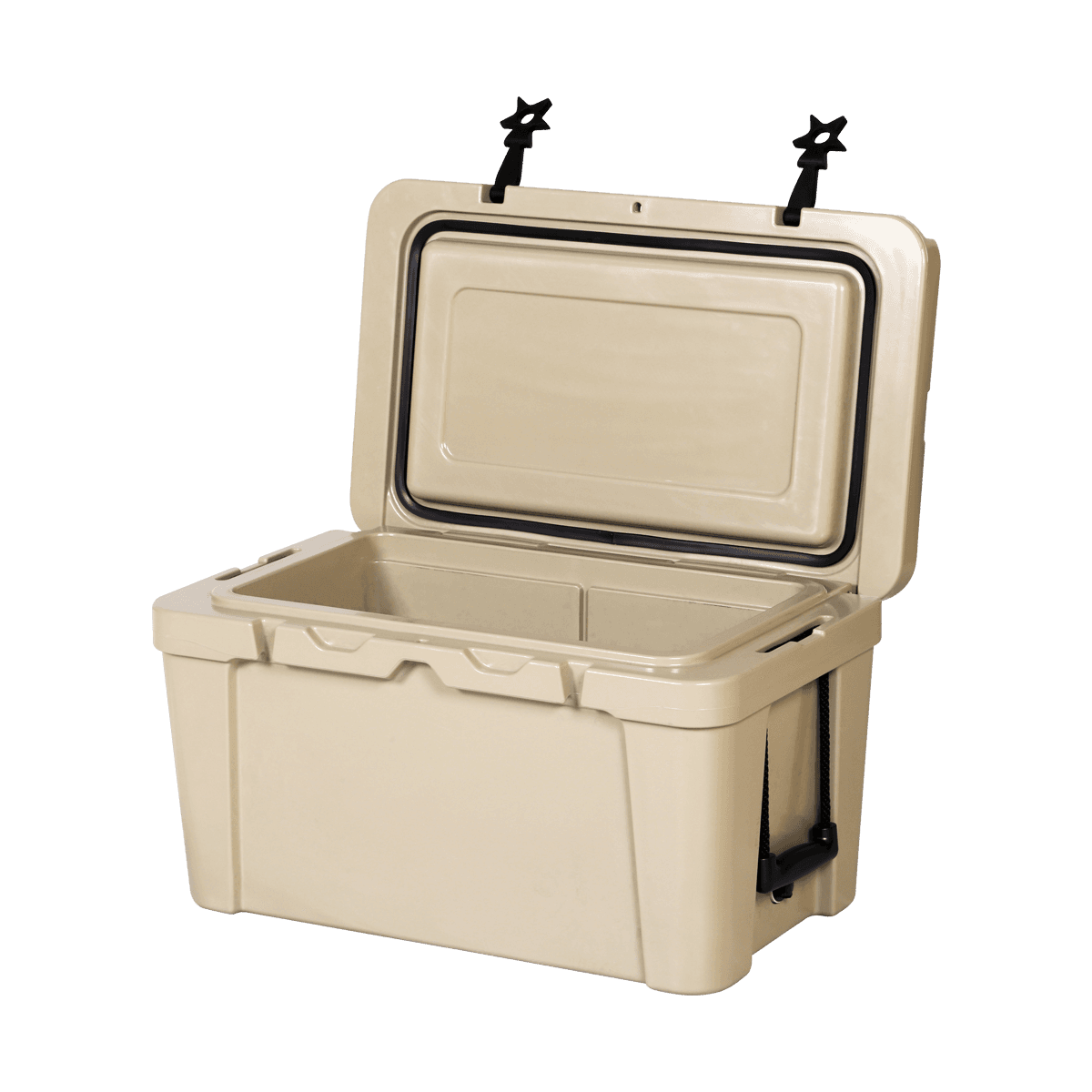

X-70L Live Seafood Transportation Tanks

Wanma 68L-70L-120L-200L insulated fish and meat tub is a convenient and well rounded small sized container and can be used for example as a fish tub, meat tub, poultry tub, as a food recycling container or whatever suits the customer. It has been popular in many areas of handling fresh food and the isolation and the lid helps with keeping quality in the product much longer than a regular plastic tub .68L-70-120-200L insulation plastic tub will help you keep your products at its best.

English

English Español

Español عربى

عربى 中文简体

中文简体

-4.png?imageView2/2/format/jp2)

-4.png?imageView2/2/format/jp2)

-2.png?imageView2/2/format/jp2)

-2.png?imageView2/2/format/jp2)

-2.png?imageView2/2/format/jp2)