1. Maintain a stable temperature environment: Insulated Pallet Containers play a key role in reducing the loss of frozen goods, mainly through their excellent insulation performance. This insulation performance comes from their multi-layer wall structure, which is usually composed of high-density polyethylene (HDPE), polyurethane foam or other insulating materials. These materials can effectively block the impact of temperature changes in the external environment on the goods and maintain the internal temperature within the ideal freezing range. This stable temperature environment is particularly important for frozen goods, because temperature fluctuations may cause frozen goods to crystallize, melt or change in quality, which in turn affects the shelf life and quality of the goods.

2. Prevent freezing cycles: During cold chain transportation, freezing cycles often occur when frozen goods are exposed to low temperature environments. This phenomenon refers to the condensation of moisture into ice under low temperature conditions, forming frost or ice layers, which may cause damage to the surface and quality of the goods. Insulated Pallet Containers effectively reduce the risk of freezing cycles by reducing temperature fluctuations and moisture penetration. Its insulation layer not only reduces the entry of moisture, but also slows down the rate of internal temperature changes, keeping the surface of the goods dry and the overall quality.

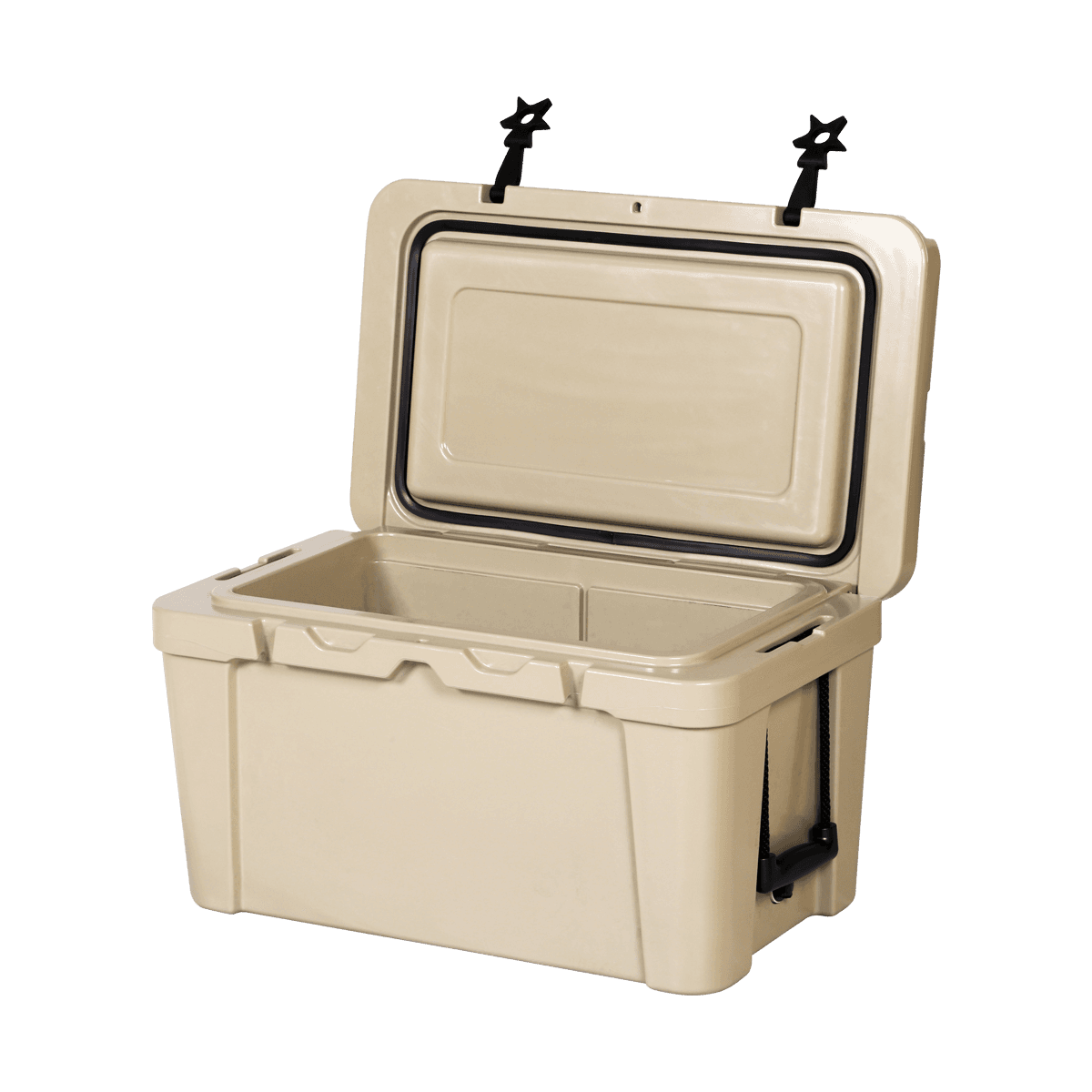

3. Provide good sealing: Insulated Pallet Containers are usually designed with an efficient sealing system that can effectively prevent external air, moisture or contaminants from entering the container. This sealing not only helps maintain the freshness and quality of frozen goods, but also reduces the impact of external factors on the goods. In cold chain logistics, even slight temperature changes or penetration of external contaminants may cause the quality of goods to deteriorate or deteriorate, so the excellent sealing of Insulated Pallet Containers is particularly important.

4. Prevent physical damage: In addition to temperature and humidity control, the structural design of Insulated Pallet Containers also takes into account the physical protection of frozen goods. These containers are usually made of durable materials with strong pressure and impact resistance. During the transportation and handling of goods, the containers can effectively reduce the impact of external shocks on the goods and prevent damage caused by extrusion, collision or vibration. This physical protection not only extends the shelf life of the goods, but also reduces losses and scrap rates caused by unexpected events during transportation.

5. Reduce cold chain interruptions: Cold chain interruptions refer to the phenomenon that temperature control fails or fluctuates due to various factors during transportation, thereby affecting the quality and safety of goods. Insulated Pallet Containers effectively reduce the risk of cold chain interruption through their stable temperature control capabilities and excellent insulation performance. This stability not only ensures the quality and freshness of frozen goods throughout the supply chain, but also reduces returns and losses caused by cold chain interruptions, improving the efficiency and reliability of the overall supply chain.

6. Increase transportation efficiency: Insulated Pallet Containers not only protect frozen goods from the outside environment, but also improve transportation efficiency. Since the quality and freshness of the goods are protected, the possibility of goods returns and losses is reduced, and transportation costs and risks are reduced. In addition, the smoothness and efficiency of the transportation process are also improved, because the goods no longer incur additional transportation and compensation costs due to quality problems or losses.

English

English Español

Español عربى

عربى 中文简体

中文简体

-4.png?imageView2/2/format/jp2)

-4.png?imageView2/2/format/jp2)

-2.png?imageView2/2/format/jp2)

-2.png?imageView2/2/format/jp2)

-2.png?imageView2/2/format/jp2)