1. Application of intelligent temperature control system

Wireless sensor technology

Principle: By embedding sensors in cargo packaging or containers, temperature, humidity and other key parameters can be monitored in real time, and data can be transmitted to the cloud platform for analysis and recording.

Advantages: Improve the accuracy and real-time performance of temperature monitoring, facilitate remote operation of monitoring personnel, and reduce human errors.

Internet of Things (IoT) technology

Implementation method: Through the interconnection of sensors, smart devices and cloud platforms, temperature data sharing and traceability of the entire chain can be realized.

Effect: Make the cold chain logistics process more transparent, reliable and efficient, and facilitate timely detection and resolution of temperature fluctuation problems.

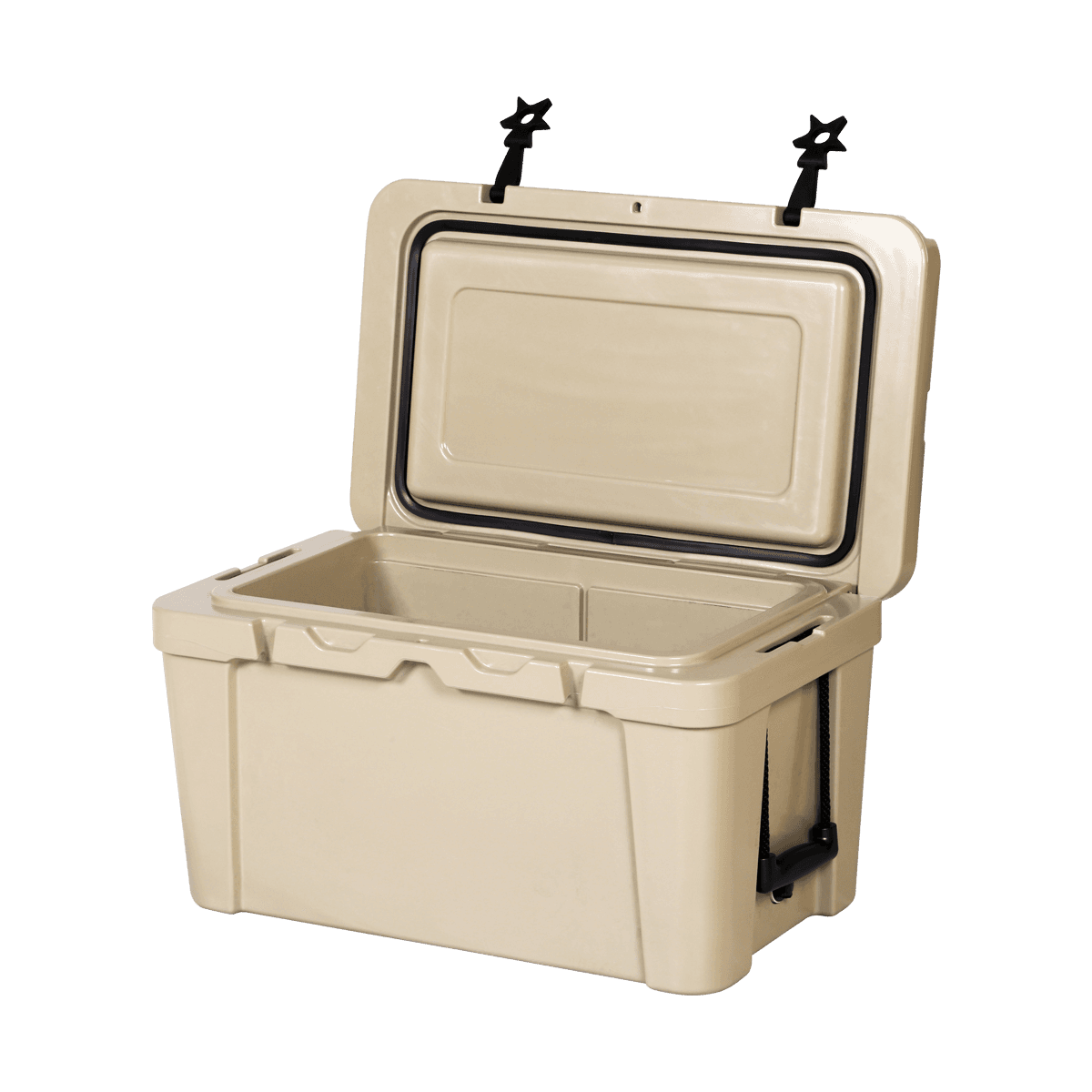

2. Advanced thermal insulation materials and technologies

Double-layer thermal insulation materials

Application: In order to prevent materials with good thermal insulation performance from shrinking in high temperature environments, double-layer thermal insulation materials are used for treatment.

Effect: The outer layer uses PU foam plastic for insulation, and the inner layer uses low-temperature thermal insulation materials to better meet the needs of refrigerated transportation and reduce the impact of external temperature on internal temperature.

New thermal insulation materials

R&D: Continuously explore and develop new materials with higher thermal insulation performance, such as aerogels.

Advantages: These materials can more effectively isolate external heat, reduce temperature fluctuations, and ensure the stability of cold chain transportation.

3. Temperature monitoring and early warning system

GPS temperature monitoring system

Function: Install a GPS temperature monitoring system during long-distance transportation to monitor temperature changes in the car in real time.

Advantages: It is convenient for managers to monitor temperature changes in real time in the office, and promptly discover and deal with temperature fluctuations.

Temperature abnormality alarm device

Implementation method: The vehicle is equipped with a temperature recorder and an alarm device. When the temperature in the car exceeds the set range, the alarm is automatically triggered.

Effect: Through sound and light alarms and SMS alarms, it is ensured that the relevant responsible persons can obtain the alarm information in time and deal with it, so as to prevent food quality problems caused by temperature fluctuations.

4. Optimize transportation process and strategy

Precooling treatment

Measures: Before loading the goods in the refrigerated truck, precool the car to ensure that the temperature in the car meets the set requirements.

Effect: Reduce the temperature rise during transportation and keep the product temperature stable.

Reasonable route planning

Strategy: Reasonably plan the transportation route according to factors such as transportation distance, weather conditions, and traffic conditions.

Advantages: Reduce transportation time and the number of stops along the way, and reduce the risk of temperature fluctuations.

5. Improve equipment maintenance and management level

Regular maintenance and inspection

Measures: Regularly maintain and inspect cold chain Logistics And Cold-Chain Containers equipment to ensure its normal operation.

Importance: Timely discover and solve equipment failures and potential problems to prevent temperature fluctuations caused by equipment failures.

Train operators

Content: Strengthen the training and management of operators to improve their awareness of the importance of cold chain transportation.

Effect: Ensure that operators can master equipment operation skills, standardize operation procedures, and reduce temperature fluctuations caused by human factors.

-4.png?imageView2/2/format/jp2)

-4.png?imageView2/2/format/jp2)

-2.png?imageView2/2/format/jp2)

-2.png?imageView2/2/format/jp2)

-2.png?imageView2/2/format/jp2)