1. Transportation and Storage

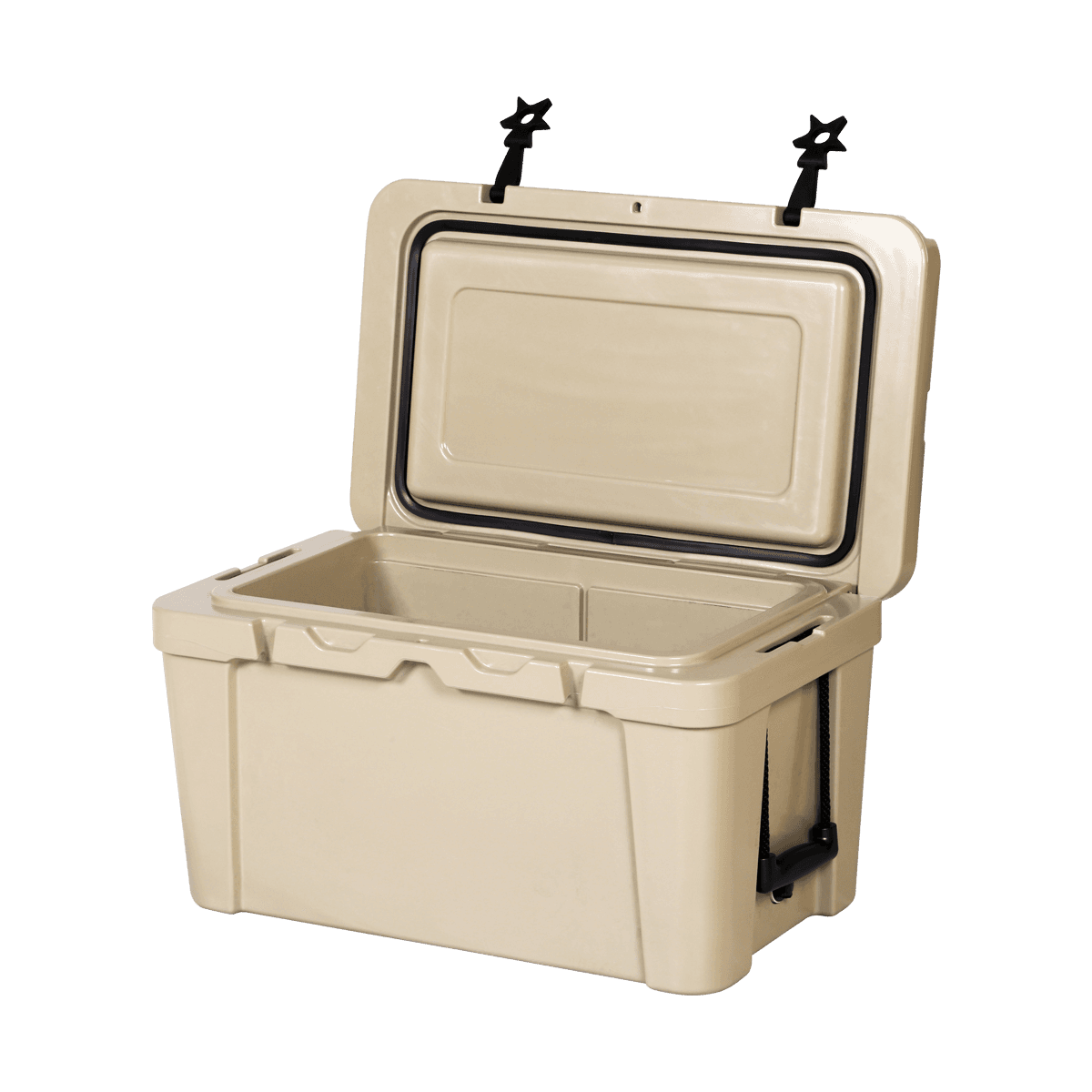

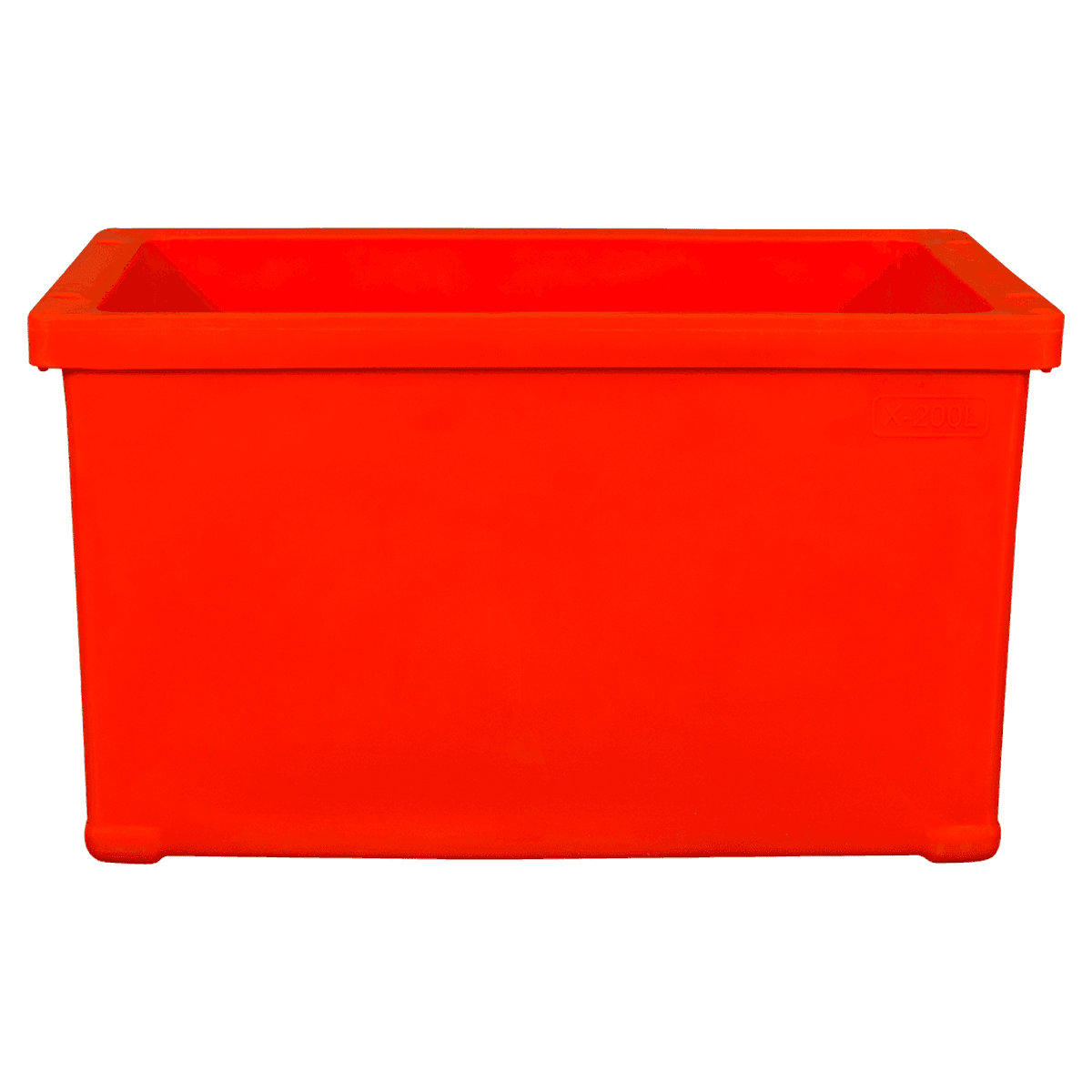

The transportation and storage functions of plastic containers for the poultry industry are crucial. Designed to withstand the various pressures and impacts during transportation, these containers are usually made of high-strength, durable plastic materials to ensure that they are not easily damaged during long-distance transportation. Through reasonable design, these containers can be stacked effectively, saving space and making the transportation process more efficient. In terms of storage, the moisture-proof and sealing properties of the containers help to maintain the freshness of poultry and its products, reduce bacterial growth, and thus extend the shelf life. The design of the containers also takes ventilation into consideration, and some models are equipped with ventilation holes to ensure that the poultry maintains the appropriate temperature and humidity during transportation, which is essential to prevent meat from spoiling. Therefore, choosing the right plastic container is an important step in ensuring the quality and safety of poultry products.

2. Hygiene and Safety

In the poultry industry, hygiene and safety are the top priorities. Plastic containers are usually made of food-grade materials, which do not contain harmful chemical ingredients and meet national and international hygiene standards. This design concept not only ensures the safety of poultry and its products, but also reduces potential food safety hazards. The smooth surface of the container makes cleaning and disinfection simple, and operators can easily remove residues and contaminants, ensuring that the container meets hygiene standards before and after use. The closed design of the container prevents the entry of external contaminants, thereby reducing the risk of cross-contamination. This safety is particularly important during transportation, as unqualified containers may cause poultry products to be contaminated and affect consumer health.

3. Sorting and grading

In the poultry industry, sorting and grading are important links to ensure product quality. Plastic containers are usually equipped with identification and labeling systems, so that poultry of different species, weights and qualities can be easily stored separately. Through standardized container design, operators can quickly identify and handle different types of products, thereby improving work efficiency. For example, during slaughter and processing, containers can be classified according to different species such as chickens, ducks, geese, etc., ensuring that each product can be handled and stored under appropriate conditions. The compartmentalized design of the container allows different grades of products to be stored in the same container. This flexibility not only optimizes space use, but also makes inventory management more efficient and reduces management costs.

4. Improve work efficiency

The production process of the poultry industry often requires efficient logistics management, and plastic containers play an important role in this regard. Through standardized design, the use of plastic containers can reduce the time and labor costs of product handling. For example, these containers are often designed to be stackable and piled, allowing for maximum storage in a limited space. During transportation and loading and unloading, operators can use equipment such as forklifts to quickly move, reducing labor consumption. At the same time, the standardized size and shape of the containers make them suitable for various means of transportation, further simplifying the logistics process. The use of containers can also reduce human errors, improve overall work efficiency, and ensure the smooth progress of the production process.

5. Reusable and environmentally friendly

In the modern poultry industry, environmental awareness is increasing, and the reusability of plastic containers has become an important consideration. Many plastic containers for the poultry industry are specially designed to be used multiple times, which not only reduces dependence on disposable materials, but also reduces operating costs. Compared with disposable containers, reusable plastic containers can significantly reduce resource waste in long-term use. Furthermore, with the popularization of the concept of sustainable development, many manufacturers have begun to use recyclable materials to produce plastic containers, which meet environmental standards. This shift not only helps to reduce the burden on the environment, but also enhances the social responsibility of enterprises, thereby winning a good reputation in the market. By adopting environmentally friendly materials and production processes, the poultry industry is gradually achieving green transformation and promoting sustainable development.

-4.png?imageView2/2/format/jp2)

-4.png?imageView2/2/format/jp2)

-2.png?imageView2/2/format/jp2)

-2.png?imageView2/2/format/jp2)

-2.png?imageView2/2/format/jp2)