1.Outer Shell: The outer shell of insulated plastic containers is typically crafted from durable plastic materials like polypropylene (PP), polyethylene (PE), or polycarbonate (PC). These materials are selected for their robustness, lightweight nature, and resistance to impact, making them ideal for withstanding the rigors of daily use and transportation. Polypropylene, for instance, is known for its toughness and chemical resistance, ensuring that the container maintains its structural integrity even when exposed to harsh conditions. Similarly, polyethylene offers excellent flexibility and resistance to cracking, enhancing the durability of the container, while polycarbonate provides exceptional strength and clarity, allowing users to easily monitor the contents of the container without compromising its structural integrity.

2.Insulation Layer: The insulation layer is a crucial component of insulated plastic containers, tasked with maintaining the desired temperature of the contents for an extended period. Expanded polystyrene (EPS) foam or polyurethane foam are commonly used as insulation materials due to their excellent thermal properties. EPS foam consists of tiny air pockets that trap heat or cold, effectively slowing down the transfer of thermal energy and preserving the temperature inside the container. Polyurethane foam, on the other hand, offers superior insulation performance due to its higher density and ability to conform to the shape of the container, minimizing air gaps and maximizing thermal efficiency. Additionally, some advanced insulated containers utilize vacuum insulation technology, where the space between the inner and outer walls of the container is evacuated to create a vacuum, greatly reducing heat transfer by conduction and convection.

3.Inner Liner: The inner liner of insulated plastic containers is typically crafted from food-grade materials to ensure the safety and integrity of the stored contents. Stainless steel, glass, and BPA-free plastic are commonly used for this purpose. Stainless steel is prized for its durability, resistance to corrosion, and non-reactive properties, making it an excellent choice for storing both hot and cold foods without imparting any unwanted flavors or odors. Glass offers a transparent and inert surface that does not absorb or leach chemicals, ensuring that the taste and quality of the stored food remain unaffected. BPA-free plastics provide a lightweight and shatter-resistant option for the inner liner, offering convenience and versatility while meeting stringent safety standards for food contact materials.

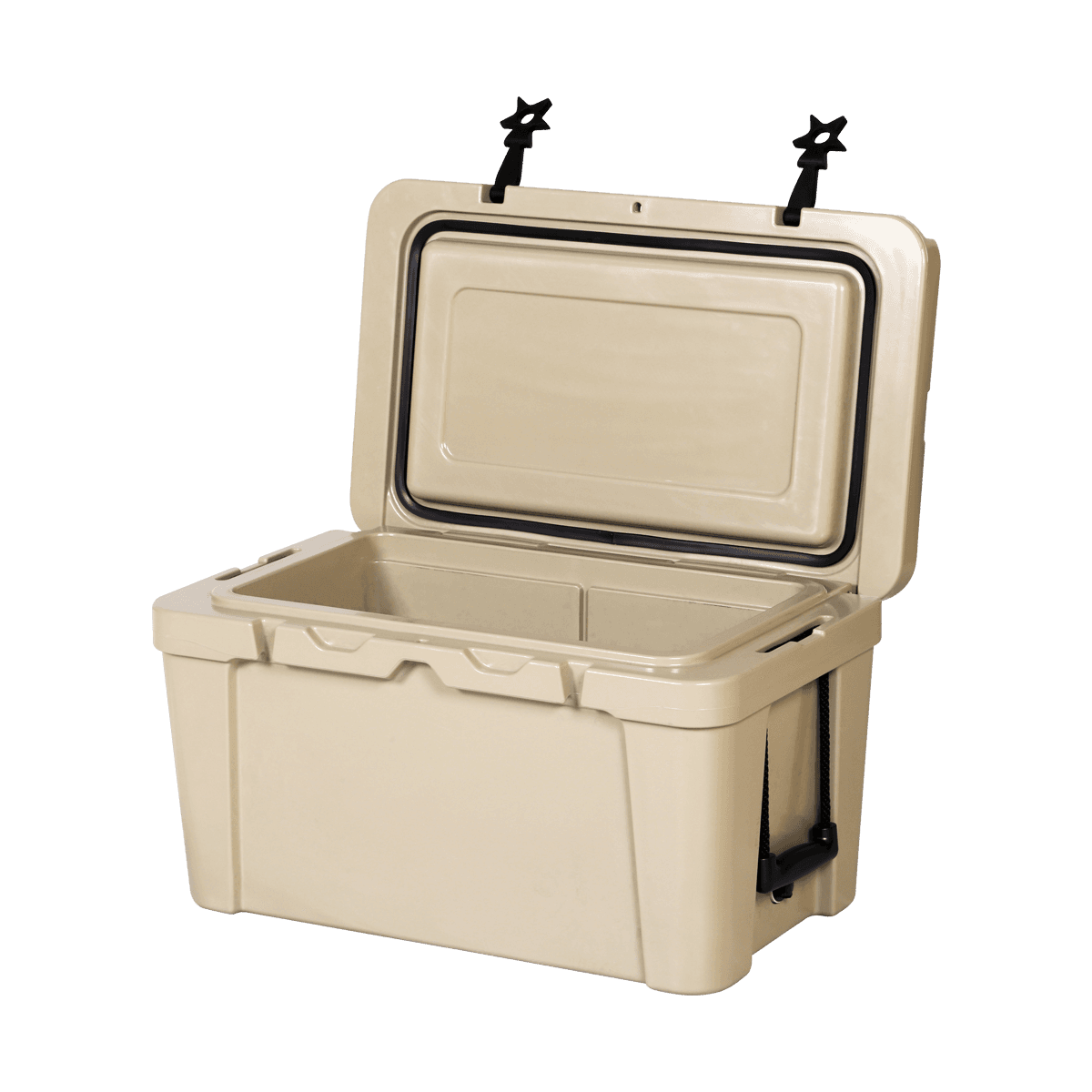

4.Sealing Mechanism: Insulated plastic containers feature a sealing mechanism designed to prevent heat or cold from escaping and to maintain the temperature of the contents. This sealing mechanism may take the form of a snug-fitting lid, a silicone gasket, or a combination of both, depending on the design of the container. Silicone gaskets create an airtight seal between the lid and the container, minimizing air exchange and heat transfer, while snap-on lids or screw-on caps provide additional security and convenience for users. The sealing mechanism plays a crucial role in preserving the freshness and temperature of the stored contents, ensuring that they remain at the desired temperature for an extended period.

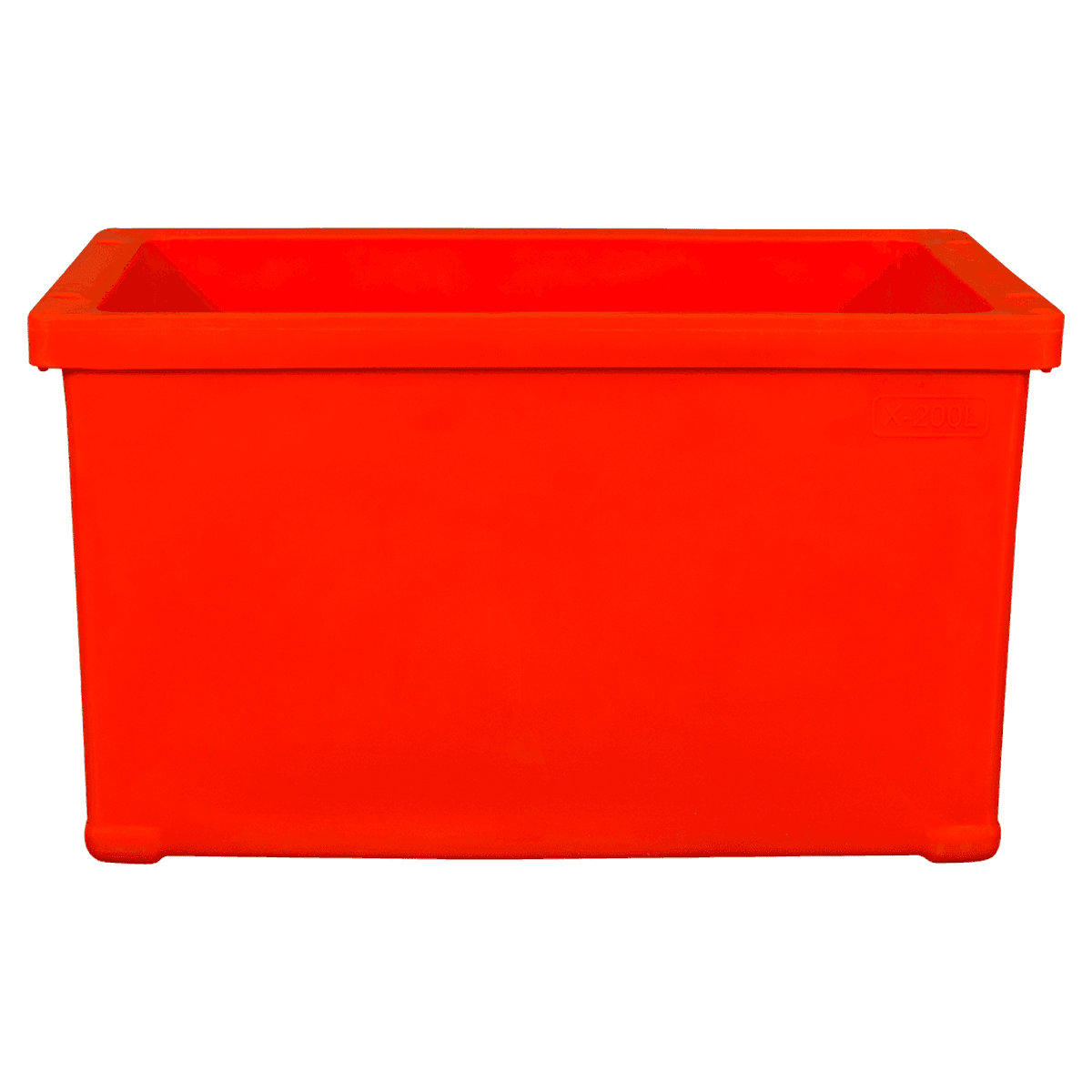

AF-1700L Extra Large Lobster Containers Seafood Industrial Use Plastic Containers

The Wanma AF-1700L PUR insulated on board handling plastic container offers a unique solution for the storage of live lobster and Tuna, handling and transportation of live lobster when use in conjunction with the 140L crates – Wanma AF-1700L insulated lobster container holds 8*140L crates for lobster. This provides an innovative solution that minimizes handing and promotes higher value ,customer satisfaction and better matketability for your lobster.

English

English Español

Español عربى

عربى 中文简体

中文简体

-4.png?imageView2/2/format/jp2)

-4.png?imageView2/2/format/jp2)

-2.png?imageView2/2/format/jp2)

-2.png?imageView2/2/format/jp2)

-2.png?imageView2/2/format/jp2)