With the vigorous development of the Internet and the Internet of Things, refrigeration is becoming more and more popular, especially in the last few links of the transportation process. From large cold food trucks to small refrigerators, the last few kilometers often reflect the transportation efficiency. The key to the success or failure of transportation, refrigerated transportation containers have its important significance!

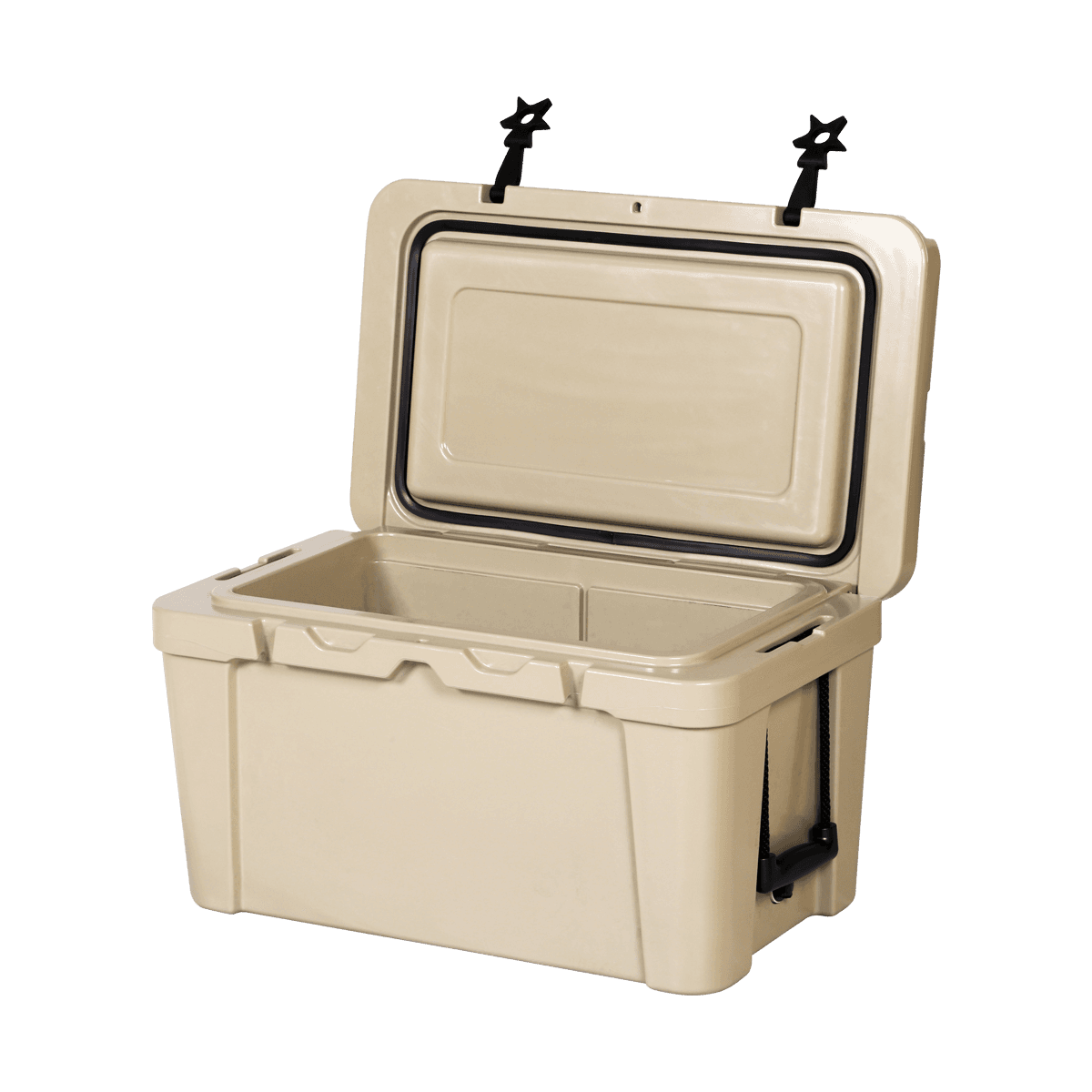

The refrigerated incubator not only refers to its small size and weight, but also low cost and low investment pressure for enterprises. However, compared with refrigerated trucks and other refrigerated transportation equipment, it is more flexible and personalized, and is more suitable for the product characteristics of small batches, multi-batches, multi-variety, and multi-temperature zones of fresh food e-commerce, and it is more convenient for "door-to-door" delivery and pickup, so it actually plays an extremely important role in the entire distribution chain, especially in the last mile distribution.

At present, the main distribution method adopted in the last mile of cold chain home delivery in my country is car + incubator. Therefore, from the perspective of the entire cold chain supply chain, the incubator should be an indispensable part, just like a precision instrument. Without it, the overall efficiency will be greatly reduced, and it will not even run smoothly.

Since the home delivery link of the last mile, the development of the market has put forward many new requirements for traditional refrigerators. Some people in the industry believe that the most difficult part of the entire cold chain is the last mile, and the specific difficulty is the guarantee of the temperature and time of refrigeration. Here are some suggestions that we hope will help you:

1. Multi-variety, multi-temperature zone

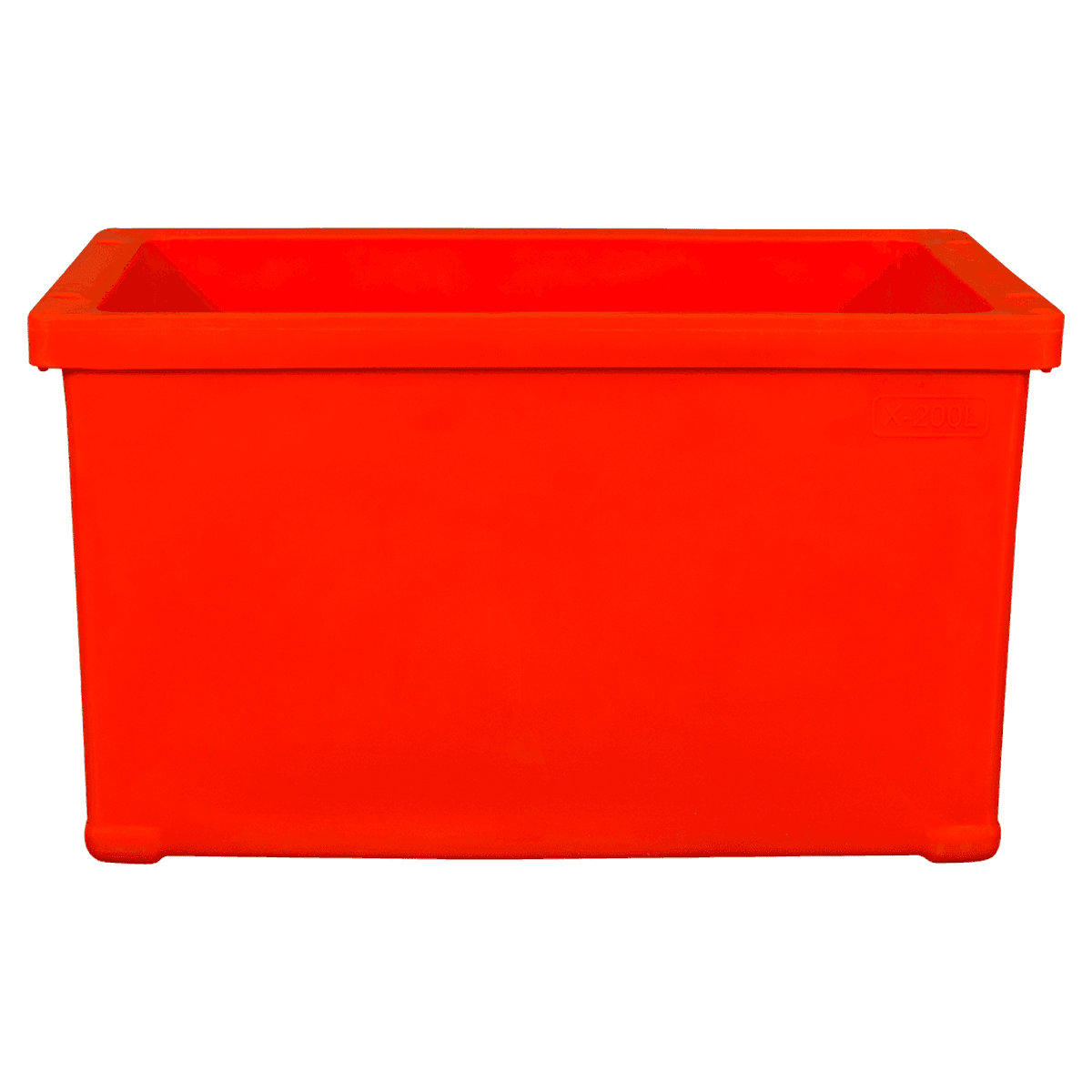

Usually, fresh products are required to be delivered to customers within 3 hours after leaving the warehouse, and even within 1 hour or half an hour. However, there are many types of fresh products and various storage temperatures. What about temperature and time protection? It is suggested that the refrigerator can be specially developed according to the customer's requirements, which can be divided into three series: cold storage, cold fresh, and frozen. They are used to store different types of food such as fruits and vegetables, fresh milk, and frozen meat, so as to achieve multiple varieties and cold storage and freezing temperatures. Complete.

2. Multiple time periods and multiple specifications

The more sizes and specifications of the incubator, the more it can satisfy customers' choice of different sizes of cold chain product packaging units. Due to the large number of cold chain products, different packaging sizes, and random combinations of products in the same temperature zone, various refrigerators and freezers of different sizes, specifications, and thicknesses can be developed for customers to choose, so that there is always one that is satisfactory, and The thermal insulation performance of the box can be based on the requirements of different products, and the cold chain time can reach 12, 24, 36 hours, etc.

3. Increase sturdiness and crash strength

In the process of express transportation and handling, cold chain home distribution boxes will inevitably suffer from dragging wear and collision damage. It is recommended to develop enhanced or reinforced insulated boxes, which can increase the firmness and anti-collision strength while improving the insulation performance, so as to Prevent the quality of cold chain home delivery from being affected, greatly improve the turnover efficiency of the incubator, and at the same time reduce the loss of frequent repairs and updates, thereby reducing the procurement cost of cold chain home delivery companies.

4. According to the special needs of customers, tailor-made

Cold chain companies will choose different transport vehicles to engage in the last-mile distribution business of the cold chain, such as vans, electric bicycles, electric tricycles, vans, etc. Insulation boxes of various sizes can be customized and developed according to the above-mentioned different carrying vehicles and spaces. We can also design and develop special opening positions and more convenient handling methods according to customer requirements, such as adding pulleys, handles, etc., to meet customer needs as much as possible. In addition, in order to prevent frostbite damage caused by the direct contact of ice sheets with fruits and vegetables, customized isolation improvements can be made inside the compartment to achieve the effect of both temperature insulation and cold transmission.

If a worker wants to do a good job, he must first sharpen his tools. The lack of good cold chain home delivery equipment is one of the reasons why many cold chain pioneers failed in the final link of the whole cold chain. Therefore, it is recommended to choose a refrigerator with many varieties, complete specifications, customization, durability, and the best comprehensive cost performance to guarantee fresh food.

Wanma is a professional Workshop and Warehouse Use Cold-chain Containers Manufacturer, if you are interested in the products, please contact us.

-4.png?imageView2/2/format/jp2)

-4.png?imageView2/2/format/jp2)

-2.png?imageView2/2/format/jp2)

-2.png?imageView2/2/format/jp2)

-2.png?imageView2/2/format/jp2)