Cold-chain containers are essential tools for maintaining the integrity of temperature-sensitive goods throughout their transportation journey. From pharmaceuticals and fresh produce to perishable foods and vaccines, these containers ensure that products are kept within specific temperature ranges, preserving their quality and safety. By providing stable temperature control, protecting against environmental factors, and offering real-time monitoring, cold-chain containers play a crucial role in maintaining product quality and extending shelf life.

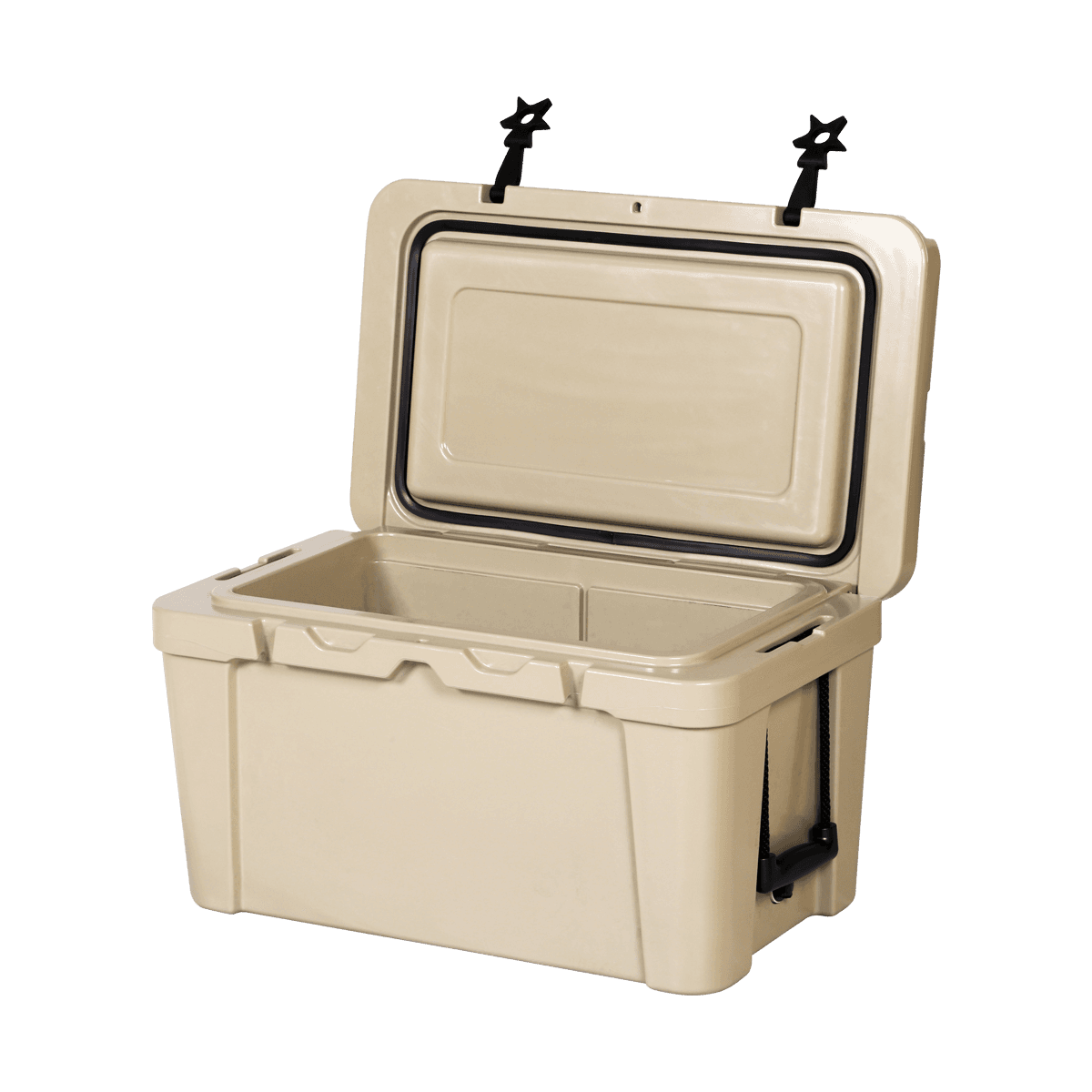

One of the primary functions of cold-chain containers is to provide consistent temperature control. These containers are engineered to keep goods at a stable temperature, which is especially important for items that are sensitive to heat or cold. For example, vaccines, which require specific cold storage conditions, can lose their effectiveness or potency if exposed to even minor temperature fluctuations. Similarly, fresh produce like fruits, vegetables, and meats can spoil quickly if not kept at the correct temperature. Cold-chain containers are designed to maintain these precise conditions, ensuring that goods remain within the optimal temperature range throughout transit. This is achieved through the use of highly effective insulation, refrigeration units, and temperature monitoring systems built into the container's structure.

In addition to temperature control, cold-chain containers also protect products from external environmental factors. These containers are equipped with features that shield goods from humidity, sunlight, and air exposure—elements that could compromise the quality of the products. For instance, dairy products and frozen foods are highly susceptible to changes in temperature and moisture levels, which can lead to spoilage or the loss of texture and flavor. The airtight seals and insulated walls of cold-chain containers provide a protective barrier that reduces the risk of contamination from these environmental factors, ensuring that products arrive at their destination in the same condition they were in when they left the warehouse.

Modern cold-chain containers are also equipped with advanced technology that allows for real-time monitoring of temperature and humidity levels. Sensors and GPS tracking systems embedded in the containers continuously monitor the internal environment, alerting both shippers and recipients if there are any deviations from the required conditions. This level of visibility into the transport process not only ensures that products are kept at the right temperature but also allows for immediate corrective action if issues arise. For example, if a refrigeration unit fails or the temperature spikes, the system can send an alert to the logistics team, enabling them to address the issue before the goods are affected. This proactive approach reduces the chances of product damage during transit and helps maintain the highest product quality.

Cold-chain containers also contribute to extending the shelf life of perishable products. By maintaining the appropriate temperature throughout the supply chain, these containers slow down the natural degradation processes of items like food, medicine, and biological samples. The ability to keep products at optimal conditions for longer periods means that goods can travel farther distances and still arrive in perfect condition. This is especially important in global supply chains, where goods often have to be transported over long distances and across different climates. For industries like pharmaceuticals, where the efficacy of a drug can be compromised by improper storage, the ability to extend shelf life can be a game-changer, reducing waste and ensuring that products reach the end consumer without losing their effectiveness.

English

English Español

Español عربى

عربى 中文简体

中文简体

-4.png?imageView2/2/format/jp2)

-4.png?imageView2/2/format/jp2)

-2.png?imageView2/2/format/jp2)

-2.png?imageView2/2/format/jp2)

-2.png?imageView2/2/format/jp2)