In the modern logistics system, the transportation of fresh products has always been a very challenging task. Compared with general goods, fresh products have extremely strict requirements on temperature, humidity, and transportation time. Any negligence may lead to quality degradation, deterioration, or even the scrapping of the entire batch. The emergence and continuous upgrading of cold chain containers are born to solve this pain point. It is not only an indispensable core equipment in cold chain logistics, but also an important means to ensure the quality of fresh products.

The core function of cold chain containers is to provide a constant low temperature environment throughout the process. By integrating an advanced temperature control system, it can accurately adjust the temperature from minus 30℃ to room temperature, and ensure that the temperature inside the box is always maintained within the set range. This constant temperature effect is not only applicable to low-temperature categories such as frozen meat, seafood, and ice cream, but also to fruits, vegetables, dairy products, and other commodities that require a refrigerated environment. During transportation, constant temperature can effectively inhibit microbial reproduction and biochemical reactions, slow down the metabolic rate of products, thereby greatly extending the shelf life and ensuring that the products still maintain their original taste, color and nutrients when they arrive at the terminal.

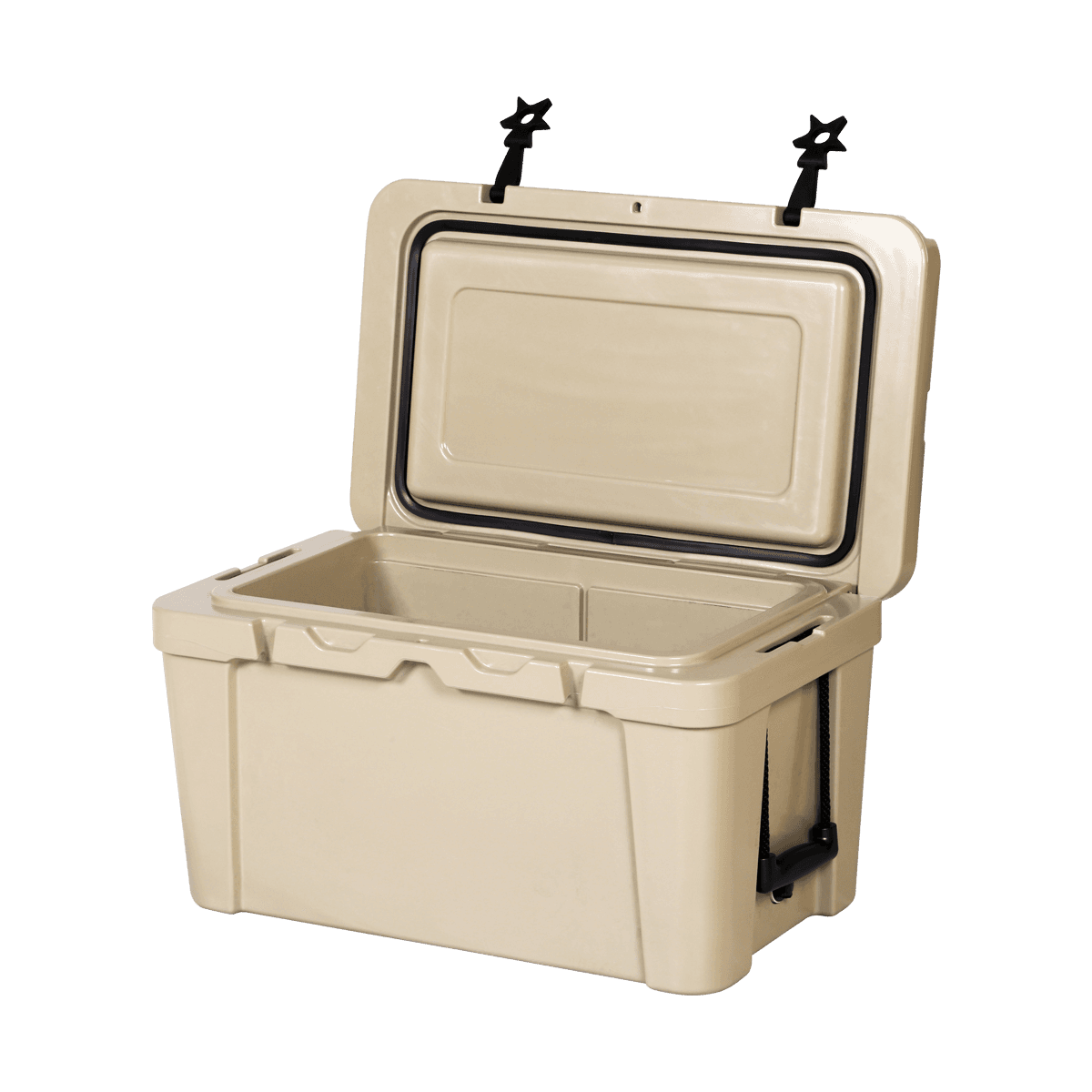

In addition to precise temperature control, the structural design of cold chain containers also plays an important role. High-efficiency insulation materials are one of the keys, such as high-density polyurethane foam or vacuum insulation panels. They have excellent insulation performance and can effectively block heat and cold exchange even in high or low temperature environments, reducing the energy consumption of the box. At the same time, the outer shell of the cold chain container is usually made of multi-layer composite metal material, which is not only strong and durable, but also has the characteristics of corrosion resistance, waterproofness, and collision resistance, ensuring safe operation in complex and changing transportation environments. This "internal and external" design enables the cold chain container to maintain the quality of the goods to the greatest extent without being affected by the outside world even during long-distance and long-term transportation.

With the development of the Internet of Things and intelligent technology, modern cold chain containers are gradually evolving towards digitalization and intelligence. Many high-end models are equipped with intelligent monitoring systems that can record and upload key data such as temperature, humidity, access control status, power, GPS location, etc. to the cloud platform in real time. No matter where they are, operators or customers can remotely view the transportation status through mobile or computer terminals to achieve real-time control of the goods. Once an abnormal situation occurs, such as temperature fluctuation, power outage, door opening, etc., the system will immediately trigger the alarm mechanism and notify relevant personnel to take timely countermeasures to avoid the expansion of the problem. This efficient early warning and intervention mechanism greatly reduces the potential risks in the fresh food transportation process.

Cold chain containers are also very flexible in actual use. It can not only adapt to different means of transportation, such as trucks, container ships, railway refrigerated trucks and even air transportation, but also be customized according to different needs, such as setting up multi-temperature zone modules, adopting pull-out shelf structures, and designing quick loading and unloading interfaces. These designs not only improve loading and unloading efficiency, but also adapt to the trend of diversification and decentralization of modern fresh food supply chains. Especially in scenarios such as e-commerce fresh food and cross-border cold chains, cold chain containers are becoming an important tool for brands to ensure delivery quality and win consumer trust with their excellent efficiency and stability.

English

English Español

Español عربى

عربى 中文简体

中文简体

-4.png?imageView2/2/format/jp2)

-4.png?imageView2/2/format/jp2)

-2.png?imageView2/2/format/jp2)

-2.png?imageView2/2/format/jp2)

-2.png?imageView2/2/format/jp2)