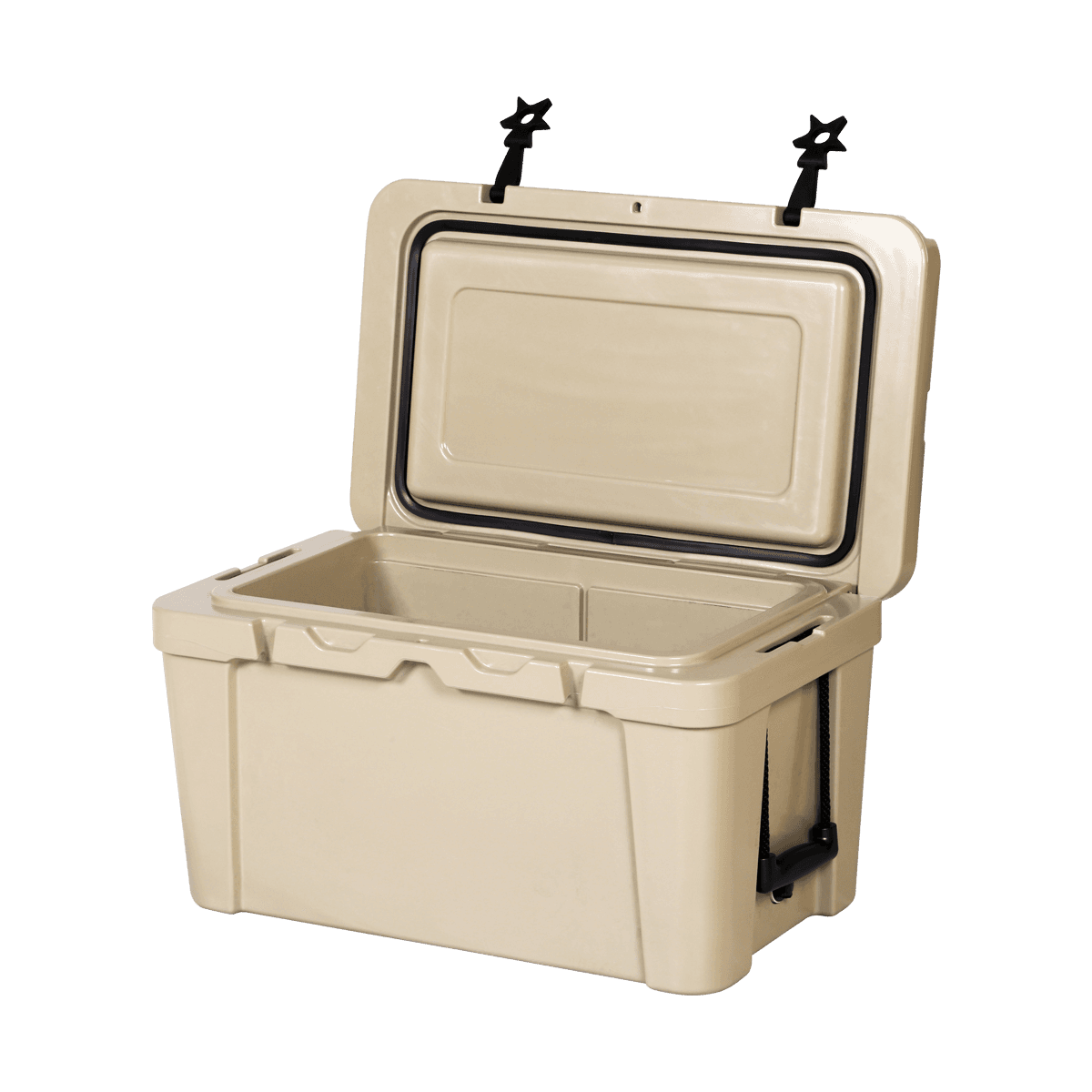

Cold chain containers play a vital role in food transportation. They are the key link to ensure food quality, extend shelf life, ensure food safety and meet strict regulatory requirements. In modern logistics, cold chain containers are not only the infrastructure for food transportation, but also an important guarantee for ensuring food safety and quality.

The most important function of cold chain containers is temperature control. During transportation, especially when transported across regions or across countries for a long time, food is easily affected by the external environmental temperature and deteriorates. Perishable foods such as fresh food, dairy products, meat and seafood are extremely sensitive to temperature. Once the temperature is too high, bacteria and pathogens in the food will multiply rapidly, causing food to spoil and even cause foodborne diseases. Cold chain containers effectively prevent these problems by keeping food in a strict low-temperature environment through built-in cooling systems and temperature control equipment. This temperature control technology can accurately adjust and maintain a specific temperature, ensuring that the food is always within the predetermined refrigerated or frozen temperature range throughout the transportation process, minimizing the risk of food deterioration.

Cold chain containers also play a vital role in extending the shelf life of food. As the distance between food production and consumption continues to increase, the transportation time of food from production and processing to the consumer's table is becoming longer and longer. Without proper temperature control, food can easily lose its freshness, and nutrients will gradually be lost at inappropriate temperatures. The cold chain logistics system effectively extends the shelf life of food through a stable low-temperature environment, allowing food to maintain its original flavor, nutrition and appearance after a long period of transportation. For example, if many fruit and vegetable products are transported in an environment with unstable temperature, their taste and appearance will soon be affected, and even lead to the loss of nutrients. Cold chain containers can ensure that the quality of these foods remains at its best and reduce waste caused by corruption.

Food safety is another critical consideration in cold chain logistics. During transportation, unstable temperature not only affects the quality of food, but also may lead to the reproduction of pathogens such as bacteria and viruses, increasing the risk of food contamination. Once food contamination occurs, it may not only endanger consumer health, but also cause companies to face huge economic losses and legal liabilities. Cold chain containers can effectively isolate changes in external temperature and maintain internal temperature stability, thereby preventing bacteria from growing due to temperature fluctuations during transportation. Cold chain containers are usually equipped with temperature recorders that can monitor temperature fluctuations during transportation in real time and issue alarms in time when abnormalities occur. In this way, transportation companies can keep track of transportation conditions at any time to ensure that food is always in a safe temperature-controlled environment.

In addition to ensuring food quality and safety, cold chain containers also play an irreplaceable role in meeting regulatory requirements. With the continuous improvement of food safety standards, many countries and regions have established strict regulatory requirements for cold chain transportation, especially for perishable foods. The use of cold chain containers not only helps companies meet these regulatory requirements, but also avoids legal risks caused by violations of regulations. For example, regions such as the European Union and the United States have strict regulations on temperature control standards for imported foods. If cold chain transportation does not meet the standards, the food may be refused entry or destroyed. Using cold chain containers that meet the standards can ensure legal compliance during food transportation and avoid unnecessary troubles.

Cold chain containers also play an important role in the global supply chain. With the development of globalization, many food companies rely not only on the domestic market, but also on cross-border trade and global supply chains. And cold chain logistics is an important guarantee to support global food trade. Whether by sea, air or land, cold chain containers ensure that food remains fresh and safe when it is transported from the producing country to the consumer market. This technological innovation allows fresh food to be enjoyed by consumers in supermarkets and on tables around the world, greatly promoting the efficiency of global food circulation and supply chains.

Cold chain containers also enhance consumer trust in food safety by improving transparency and traceability. As modern consumers pay more and more attention to the source and quality of food, cold chain transportation has become an important way for food companies to demonstrate their quality control capabilities and commitment to food safety. Many companies provide temperature control records and transportation data to prove to consumers that their food is always in a safe and compliant environment during transportation. This transparency not only enhances the brand image, but also enhances consumer trust, thereby helping companies gain a foothold in the highly competitive market.

English

English Español

Español عربى

عربى 中文简体

中文简体

-4.png?imageView2/2/format/jp2)

-4.png?imageView2/2/format/jp2)

-2.png?imageView2/2/format/jp2)

-2.png?imageView2/2/format/jp2)

-2.png?imageView2/2/format/jp2)