Product Category:

- All products

- Food use insulated plastic containers

- Seafood Industrial Use Plastic Containers

- Meat/Poultry Industrial Use Plastic Containers

- Logistics And Cold-Chain Containers

- Workshop And Warehouse Use Cold-Chain Containers

- Long Distance Live Fish Transportation Containers

- Live Seafood Farming & Transportation Tanks

- Outdoor leisure use cooler box

- Ice Cooler Container

- Ice Cooler Box

- Boats and docks use containers

- Vessels And Dock Use Ice Box

- Extra large size boats use containers

Product:

We Can Save Cost And Create Value For You

Our Products

Insulated Bulk Storage Containers Factory

-

AF-1700L Extra Large Size Boats Use Containers

AF-1700L

-

AF-380L Small Boat And Dock Use Ice Box

AF-380L

-

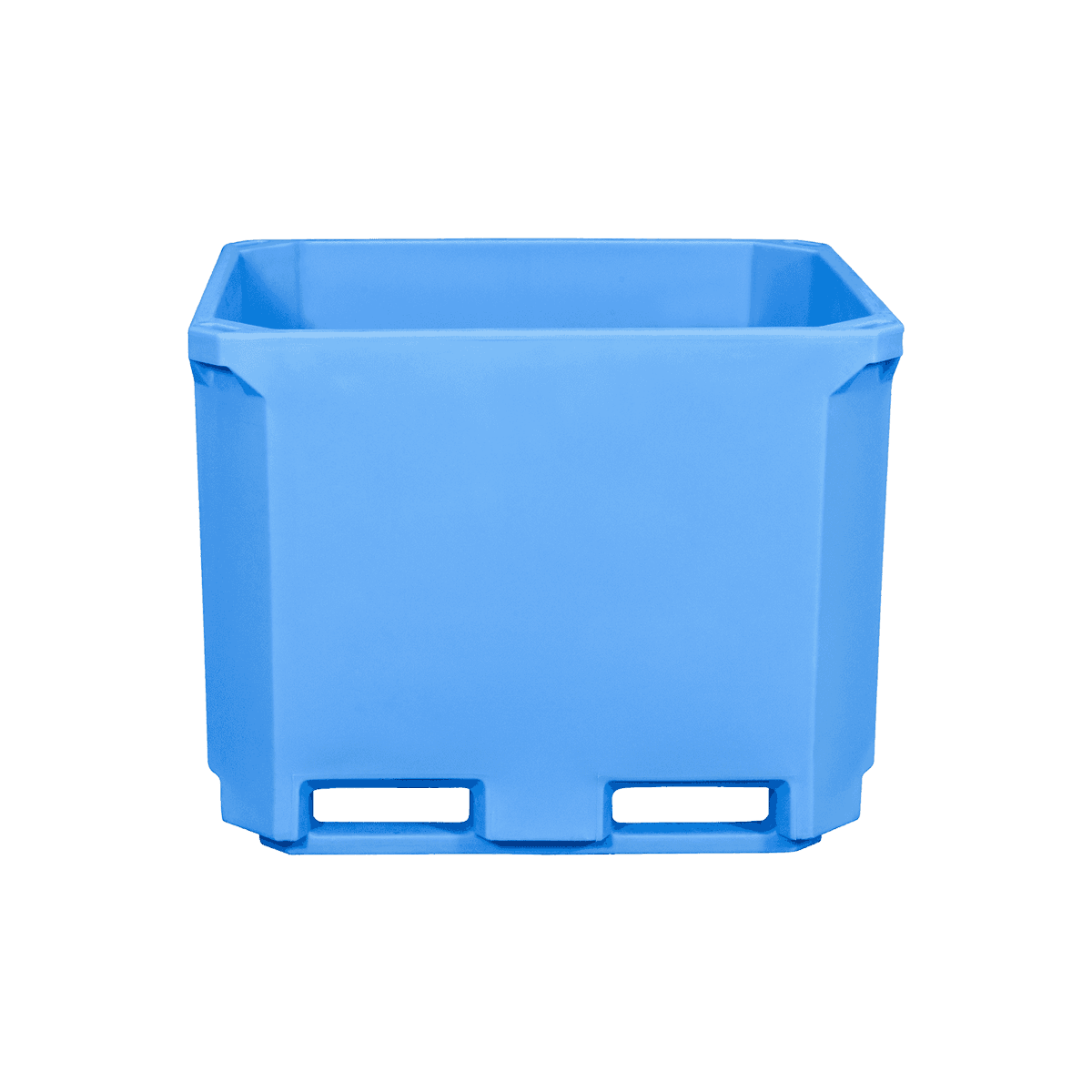

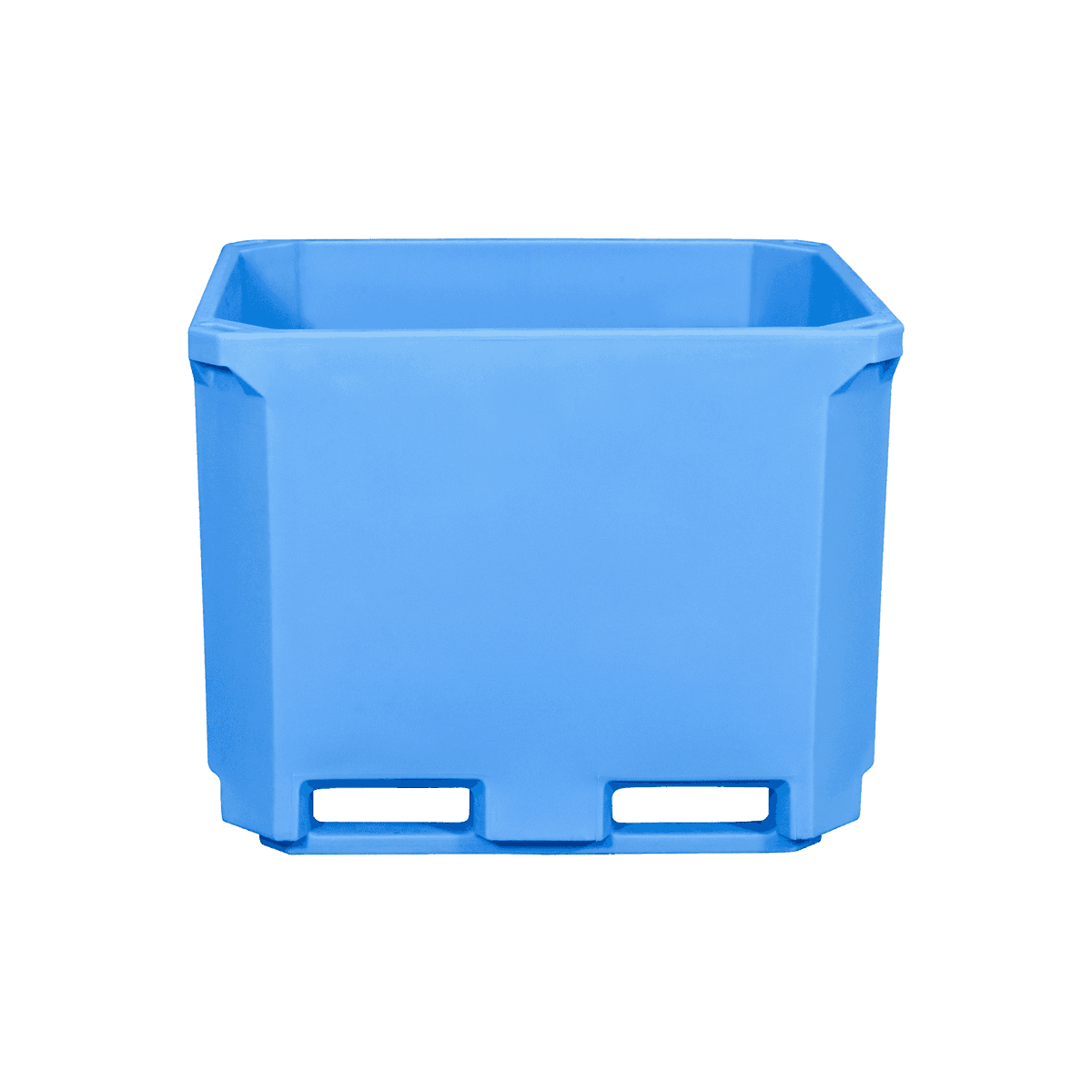

AF-1700L Extra Large Lobster Containers Seafood Industrial Use Plastic Containers

AF-1700L

-

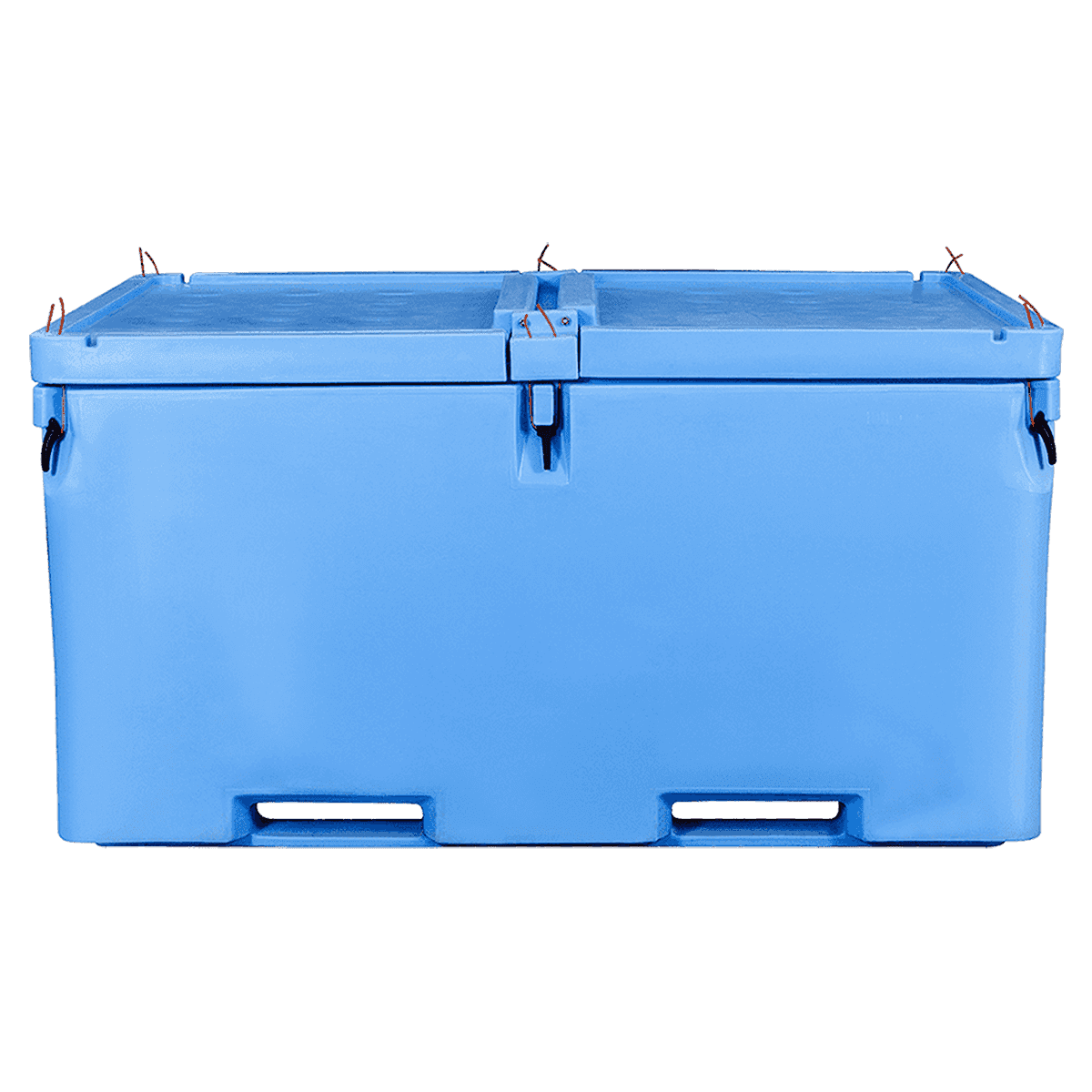

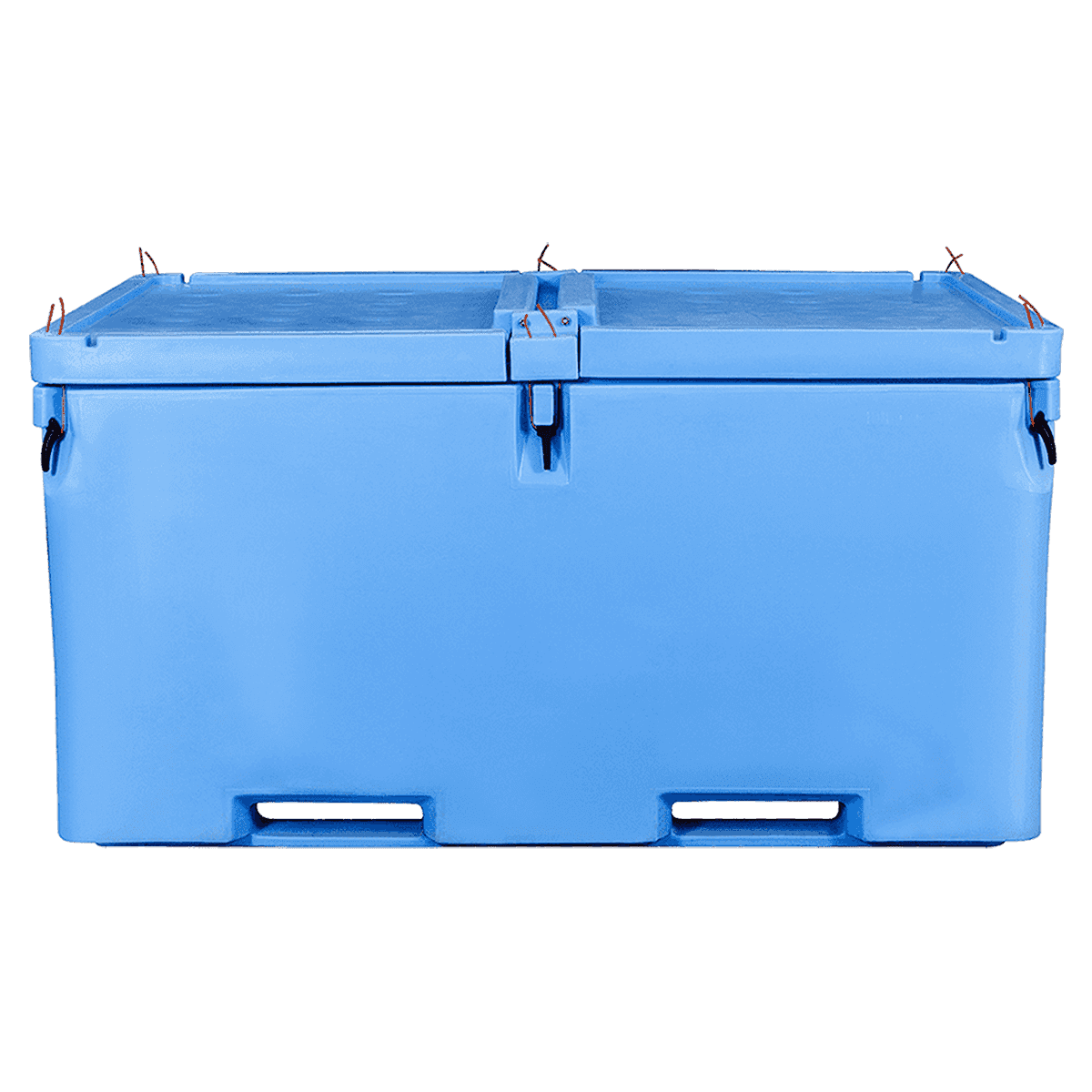

AF-1700L Insulated Bulk Container For Cold-chain Transportation And Production

AF-1700L

-

AF-1700L Large Tuna Fish Long Distance Live Fish Transportation and Storage Containers

AF-1700L

-

AF-380L Buggy Meat Cart With Wheels Meat/poultry Industrial Use Plastic Containers

AF-380L

-

-2.png?imageView2/2/format/jp2)

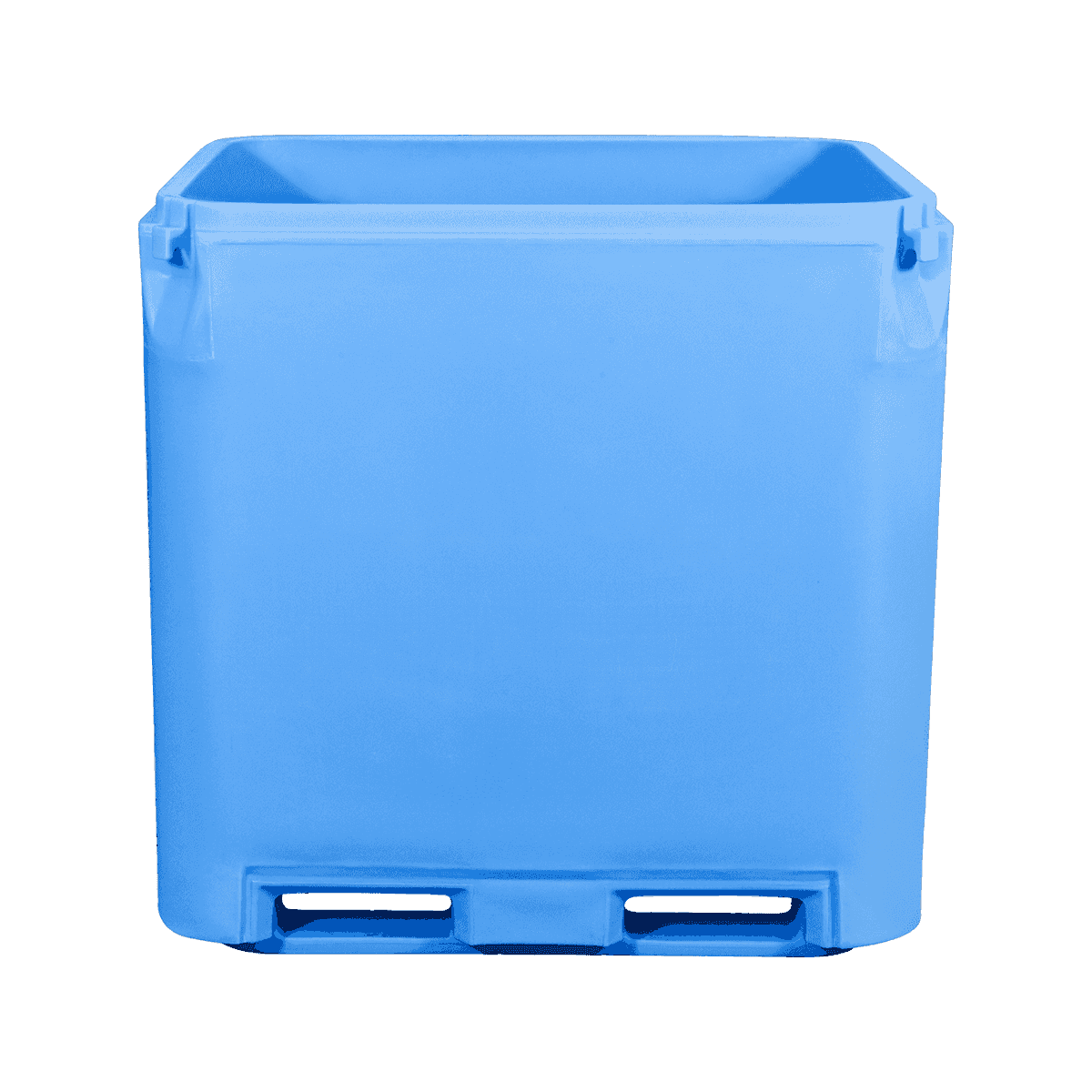

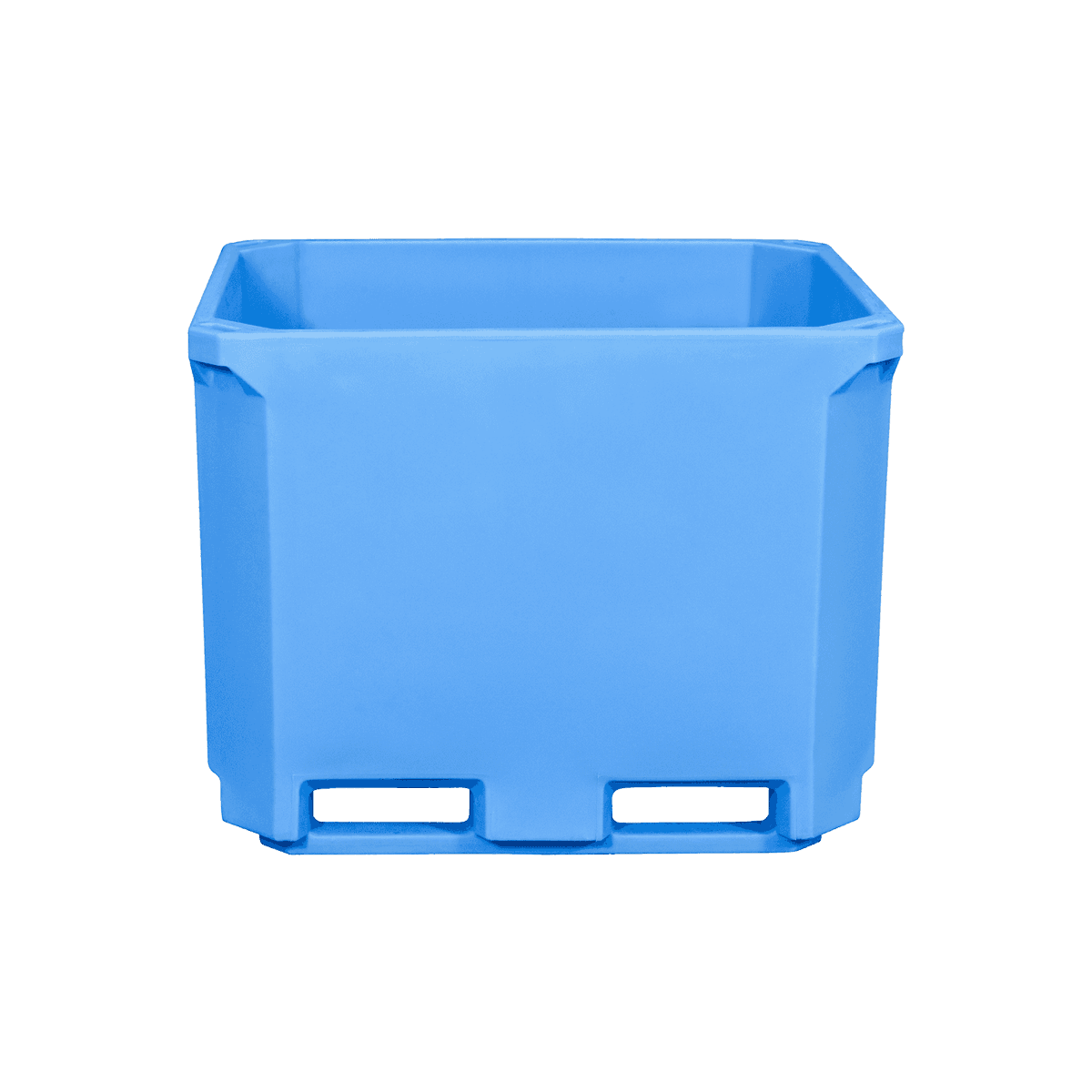

AF-660L Insulated Storage Container Meat/poultry Industrial Use Plastic Containers

AF-660L

-

-2.png?imageView2/2/format/jp2)

AF-800L Food Production Processing Meat/poultry Industrial Use Plastic Containers

AF-800L

-

AF-1000L Plastic Insulated Bins Meat/Poultry Industrial Use Plastic Containers

AF-1000L

-

.png?imageView2/2/format/jp2)

AF-340L Seafood Bins Seafood Industrial Use Plastic Containers

AF-340L

-

AF-380L Insulated Fish Tubs Seafood Industrial Use Plastic Containers

AF-380L

-

AF-460L Food Grade Fish Boxes Seafood Industrial Use Plastic Containers

AF-460L

New Product

- Food use insulated plastic containers

- Logistics And Cold-Chain Containers

- Outdoor leisure use cooler box

-

AF-1000L Plastic Insulated Bins Meat/Poultry Industrial Use Plastic Containers

AF-1000L

-

-2.png?imageView2/2/format/jp2)

AF-800L Food Production Processing Meat/poultry Industrial Use Plastic Containers

AF-800L

-

-2.png?imageView2/2/format/jp2)

AF-660L Insulated Storage Container Meat/poultry Industrial Use Plastic Containers

AF-660L

-

AF-1700L Extra Large Lobster Containers Seafood Industrial Use Plastic Containers

AF-1700L

since 2008

Ningbo Wanma Plastics Co.,Ltd.

Ningbo Wanma Plastics Co., Ltd is professional China Insulated Storage Containers Manufacturers and OEM Insulated Bulk Containers Factory, we offer wholesale Insulated Bulk Storage Containers for sale at factory price.

Established in 2008, our company is an enterprise led by a young and creative team. We have been focusing on the design, manufacture and research and development of Product products for more than ten years. We have excellent and unique technology in the field of one-piece seamless molding of double-wall containers, such as PU filling for thermal insulation barrels and sandwich structure products. All of our Product products comply with national food hygiene standards and are widely used to fully meet the storage turnover needs of various usage scenarios.

We welcome all inquiries from all over the world with warm greetings. High quality is our cornerstone, innovation is our blood. We believe we can provide better Product products with our professional team and advanced equipment. We frankly look forward to working with you in the future.

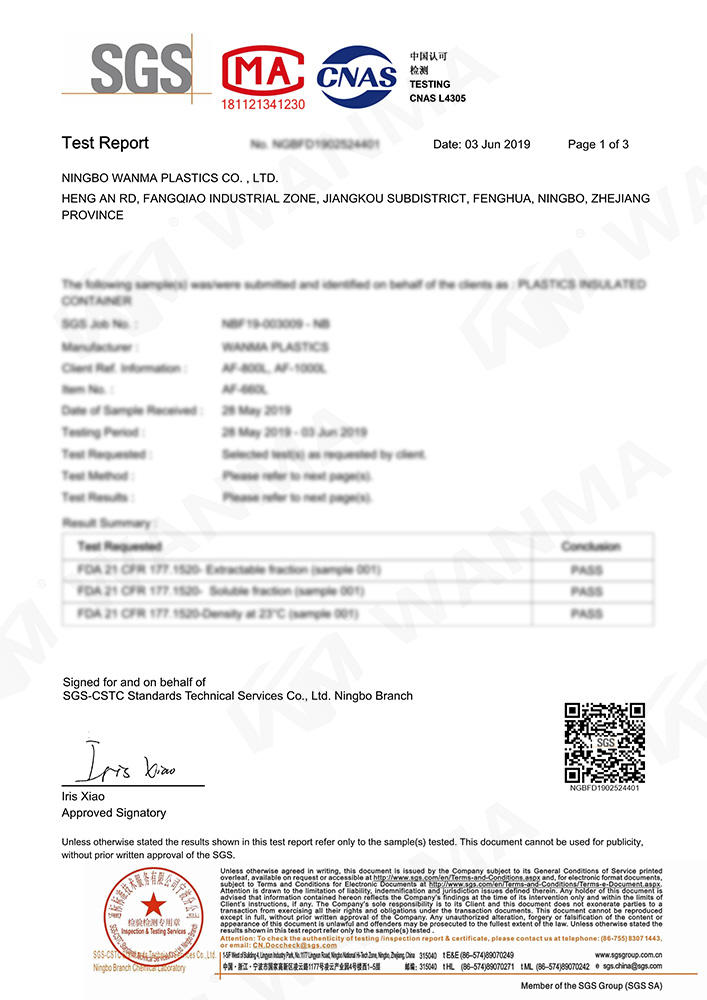

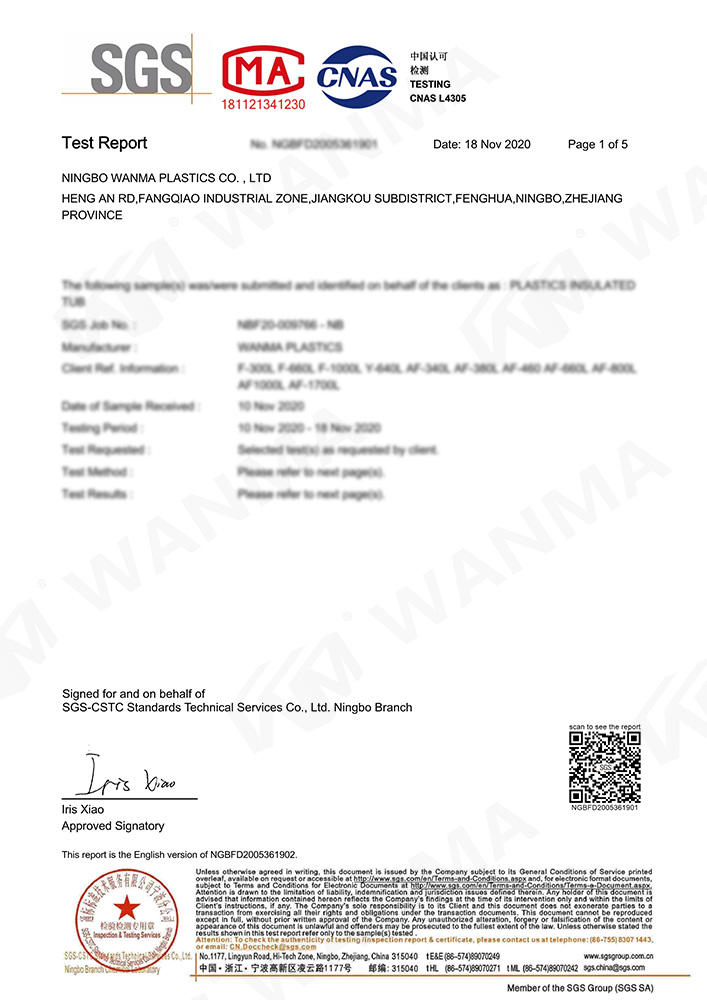

Quality and Certifications

Being an ISO-9001 certified manufacturer, we maintain manufacturing quality. Our products are made to European and international standards, and successfully pass the certification testing of CE, SGS and TUV on a regular basis.

Eu Report

FDA Report

Food Grade Report

ISO

ISO9001

Product Industry Knowledge Extension

1. Ningbo Wanma Plastics Co., Ltd. Core technology: double-wall integrated molding and ecological temperature control system

As China's leading insulated bulk containers manufacturer, Ningbo Wanma Plastics Co., Ltd. has always focused on the research and development and production of double-wall insulated containers since its establishment in 2008. Relying on a young and highly creative technical team, the company has made breakthrough progress in the field of integrated seamless molding of double-wall containers. Its patented PU foam filling technology can improve the insulation performance to the industry-leading 0.023 W/m·K, far exceeding the insulation efficiency of traditional EPS materials.

In response to the special needs of live fish transportation, Ningbo Wanma insulated bulk containers adopt a "sandwich" sandwich structure design: the outer layer is impact-modified PP material, the middle layer is a high-density PU insulation layer, and the inner layer is FDA-certified food-grade antibacterial resin. This structure can not only effectively isolate external temperature fluctuations (maintaining a temperature difference of ±2°C in the box in an environment of -20°C to 40°C), but also prevent the penetration and contamination of chemical substances during transportation. Taking the transportation of live fish as an example, the ecological temperature control system built into the container can accurately adjust the water temperature to the ecological ice temperature (ECT) of the target fish species. For example, salmon transportation needs to maintain 0-4℃, while grouper needs to be stabilized at 16-18℃, and the system error is controlled within 0.5℃.

In terms of oxygen management, Wanma has innovatively developed modular oxygenation components that can automatically adjust the dissolved oxygen concentration (DO value) according to the transportation density. Through the combination of integrated venturi tubes and nano aeration discs, the system can increase the dissolved oxygen of 1 cubic meter of water from 5 mg/L to 12 mg/L within 30 minutes to meet the needs of high-density transportation. In 2023, the technology was verified by the Chinese Academy of Fishery Sciences and achieved an industry record of 99.2% survival rate of sea bass in a 72-hour transportation experiment. As a professional OEM insulated bulk containers factory, the company can also customize exclusive functional modules such as partitions and quick drain valves according to customer needs. It has currently provided differentiated solutions for 23 countries around the world.

2. Global scenario verification: Benchmark application of Wanma Insulated Bulk Containers

Ningbo Wanma Plastics Co., Ltd.'s insulated bulk containers have been successfully used in live fish transportation networks on five continents around the world. In the Norwegian salmon export project, the 40-foot container-level solution developed by the company adopts the "dry transportation" mode: the relative humidity in the box is maintained at more than 95% through the humidity control module, and the adjustable atomization spray system is used to keep the salmon's gills moist in a waterless environment. This solution reduces the transportation loss rate from 8% of traditional water transportation to 1.5%, increases the single box loading capacity by 40%, and helps customers save more than US$1.2 million in cold chain logistics costs each year.

In the Southeast Asian market, Wanma's customized double-layer insulation box for Malaysian live shrimp exporters has demonstrated excellent weather resistance. The box body is made of UV-resistant modified materials to withstand continuous strong ultraviolet radiation in the equatorial region; the internally configured phase change refrigerant (PCM) module can maintain a low temperature environment for 48 hours in the event of a power outage. In the 2022 typhoon season, after a customer's 2,000 boxes of live shrimp were delayed for 72 hours, the survival rate was still 98.7% thanks to the stability of Wanma insulated bulk containers, directly avoiding economic losses of US$350,000.

As a professional Chinese insulated storage container manufacturer, the company is also deeply involved in the upgrade of China's local smart fisheries. At the Guangdong eel export base, the intelligent transportation system deployed by Wanma integrates 5G Internet of Things technology: each container is equipped with 32 sensors to monitor 18 parameters such as water temperature, salinity, and ammonia nitrogen concentration in real time, and the data is synchronized to multiple systems such as customs and buyers through the blockchain platform. This transparent transportation mode has increased customs clearance efficiency by 60% and successfully obtained the EU GLOBALG.A.P certification.

3. Future strategy: the path of industrial upgrading from manufacturing to ecology

Facing the annual growth trend of 7.8% in the global live fish transportation market, Ningbo Wanma Plastics Co., Ltd. is building an industrial ecology through three major strategies:

Intelligent manufacturing upgrade: Invest 20 million yuan to build a fully automated PU foaming production line, use German KraussMaffei robotic arms to achieve integrated double-wall container molding, increase production capacity to 1,500 standard boxes per month, and shorten delivery cycle to 15 days;

Zero-carbon technology research and development: Cooperate with Zhejiang University to develop a photovoltaic-driven temperature control system, integrate a flexible solar film on the top of the container (conversion efficiency 23.6%), and provide an average of 8 kWh of clean energy per day for the circulating water treatment unit;

Global service network: Set up live fish temporary transfer stations in 6 major ports such as Rotterdam and Dubai, equipped with mobile storage ponds transformed from Wanma insulated bulk containers, to solve the "last mile" survival problem in cross-border transportation.

As a supplier of wholesale insulated bulk storage containers, the company always adheres to the concept of "open cooperation". Through modular design, customers can choose the combination of basic boxes and functional components (such as aerators, water quality monitors, etc.) independently, with a minimum order quantity of 50 boxes, truly realizing "factory direct supply, customized on demand". In terms of quality control, Wanma has established 13 quality control processes from raw material testing (closed-cell rate test for each batch of PU raw materials) to finished product verification (72-hour full-load simulation transportation test) to ensure that all products meet the ISO 22000 food safety management system standards.

With more than ten years of technical accumulation, Ningbo Wanma Plastics Co., Ltd. has obtained global supply chain access qualifications including BSCI social responsibility certification and Sedex ethical trade audit. In the future, the company will continue to use insulated bulk containers as the core carrier to promote the transition of live fish transportation from "survival guarantee" to "quality optimization", and jointly define new standards for the fresh economy with global partners.

English

English Español

Español عربى

عربى 中文简体

中文简体

-2.png?imageView2/2/format/jp2)